The contents

When carrying out repairs, many quite unfairly ignored soundproofing the floor. Every family has their own rhythm of life, their habits and inclinations, so endure the constant noise coming from the neighbors, to put it mildly, uncomfortable. But also the neighbours have a right to be protected against penetration of in their flats unusual sounds, the source of which is located in your home.

There are several modern procedures for soundproofing a floor that will provide a level of comfort. It is not necessary to involve specialists, it is possible to do on their own, significantly saving and without losing thus in quality.

Soundproofing with ties ↑

Soundproofing under the floor screed is inexpensive and fairly reliable way to ensure the isolation of his apartment from outside noise.

As the material for the apartment is quite suitable cement grade 150 or 200. He did not have a high workload and well improves acoustic properties of the room. For the preparation of the composition of grade 150 400 cement is mixed with sand in proportion 1 to 3. Composition grade 200 is prepared, taking the 300 cement and sand in equal proportions.

The stages of the work ↑

- The floor surface is carefully prepared to the screed, removed all the debris and dust.

- The level of installed beacons. For this purpose, suitable slats, pieces of rebar, boards, profiles or pipes.

- Poured the solution and is equal to the rule. After mixing, it should be used within six hours. After pouring the screed it is necessary to cover the polyethylene, after a week that on the surface is not went crack.

- Beacons can be removed three days after the execution of the screed, and the remaining cavities to fill with solution.

The materials for soundproofing a floor ↑

Today, there are several options of materials for soundproofing a floor, which are easy to install. Among them are: expanded clay, polystyrene, mineral wool and perlite.

The foam is produced in slabs of a certain size. However, installation of this material, be aware that it shrinks, so it is recommended to use a hard plate.

As for the polystyrene and polyurethane foam, these materials are suitable only for floor insulation, and the proper degree of insulation they provide.

At the same time reduces mineral wool acoustic permeability and reduce heat loss. For sound insulation suitable stone or glass wool. However, keep in mind that stacking mats of mineral wool, the floor height will rise due to their thickness.

Expanded clay is used when you run dry screed also can be used for «wet». To provide greater density and strength of the backfill, selected granules of various sizes.

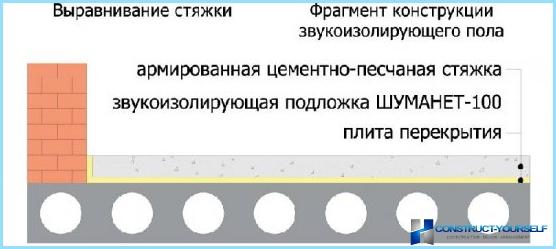

You should pay attention to such new material as «Will somanet 100», which is one of the most effective means for sound proofing. It is suitable for installation on any type of RC slabs. This material is manufactured in rolls of glass fibre, covered on one side with a polymer-bitumen composition. Its significant advantage is the small thickness.

Soundproofing a floating floor ↑

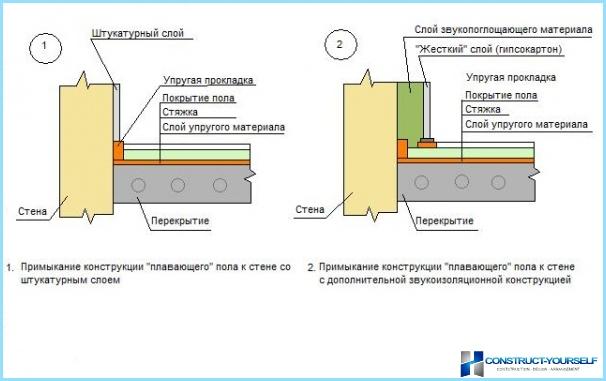

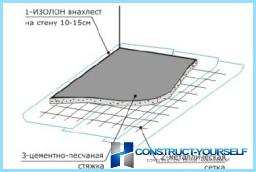

Type of screed used for the arrangement of sound insulation floating screed. She received this name because between her and W/b stove or wall of the room there is no hard coupling, it is isolated from all surfaces. However, keep in mind that the height of the floor will be rather big, so to apply the technology recommended, if you have the ceiling height. Floating coupler prevents the formation «noise bridges» and the emergence of acoustic vibrations in separate rooms.

Types of floating floors there are a few: concrete, dry screed, precast and cork.

A floating floor is a three-layer structure:

- A rigid base (concrete screed, concrete slab or wood floor).

- Backing layer. For its arrangement suitable expanded clay, polystyrene, mineral wool or izolon. If the substrate is sufficiently smooth, you can use the izolon, foam, linoleum. If there are significant irregularities, used a concrete block to fix the deficiency. To do this, between the expanded clay and the base to lay a vapor izolon or other similar material.

- Flooring. Moreover, its elements are mounted between, and around, around the perimeter between the flooring and the wall leaving a gap of 10-15 mm.

When building sound insulation floating floor, must adhere to the following rules:

- To perform the installation at room temperature and in a dry place.

- Do not use for fixing nails, glue or screws.

- Prefabricated panels for the arrangement of the modular structure of the floor is maintained for some time unopened at room temperature prior to installation.

- Installation of materials shall be perpendicular to the Windows, be sure to leave a gap between the walls.

- Installation of plinths beginning not earlier than six hours after installation.

Insulating materials for floating screed ↑

As materials for the arrangement of the floating screed is used by such modern products as humanet, vibrotek, chumashim, etc. Each of them has certain peculiarities of installation.

Somanet will fit override. It is spread on the surface of the floor, setting the stage for a bit around the perimeter of the walls to cover the height of the screed. All joints are sealed with construction tape. Excess material at the end of the work cut.

Installation somascope perform, preliminary strengthening the perimeter walls of the cushioning material. Then spread out a layer of sound insulation, joints sealed with construction tape. Top sometop covered with plastic wrap, drawing it around the perimeter a couple of inches on the wall, all the surplus after drying screed is cut.

Vibrotek placed back to back, along the perimeter, near walls, perform stacking special tapes. The material is also covered with plastic film.

Soundproofing hardwood floor ↑

Soundproofing hardwood floor is performed using a dry screed. It lay on the floor and spread with a rule. The load was distributed evenly, top-to-fit gypsum Board or chipboard. The end flanges are glued and fastened with screws.

Laying insulation under wooden base ↑

In order to protect the wooden subfloor from mechanical and air noise, and is best suited as an insulation material mineral wool. The stages of installation sound insulation of floor joists you need to perform in the following sequence:

- Prepare the ground, thoroughly cleaning it from dust and debris.

- Apply labels for laying lag. The average distance between the beams ranges from 40 to 60 cm, depending on the strength of the flooring. Also, the step between the joists affects the width of the insulating mats. Ideally, between the insulating material and the joists must not be any gaps.

- Using anchors, are attached to the joists. The width of the bars should be 3-5 cm larger than the width of insulation boards..

- Plate mineral wool laid between the joists and fastened with dowels, if they adjoin each other not tightly.

- The top is placed a waterproofing layer, the most common option is the use of polyethylene film. It is laid overlapping each other and connect the sheets together with construction adhesive tape.

- Lagi sewn planks, chipboard or other material, zashtukaturivat the joints between the sheets.

- Floor is sheathed finishing material.

Concrete screed with heat insulator ↑

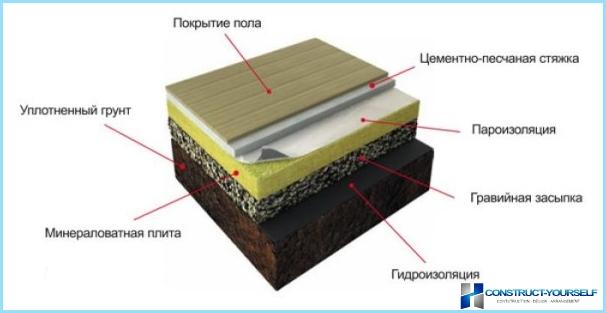

To create a floor Soundproofed to conventional screed adds a few extra layers.

- The surface is prepared and cleaned.

- Poured a thin levelling layer of screed.

- Fit insulating material, tightly, to avoid gaps.

- Laid waterproofing layer (that may be a plastic film, bonded construction tape).

- Fills with concrete. The thickness of the layer is about 5 cm.

- In the casted solution layer is placed a small reinforcing mesh.

- Using a rule, the surface is leveled.

Soundproofing under laminate and linoleum ↑

Choosing as a floor covering laminate, the technology of its styling provides a special substrate, which performs the function of soundproofing the floor. In addition, she is a heater and is used for correct distribution of load on the laminate and base. For these purposes often use cork boards or izolon. They rolled on the surface of the base. Laying is done butt joints glued with construction adhesive tape.

Performing precast floating floor for laying laminate, pre-leveled base. You can leave the old flooring, if it is sufficiently smooth, the concrete floor is not necessary.

On the prepared base substrate is placed, on top of stacked laminate Board, have them perpendicular to the window. Between the wall and laminate be sure to leave a small gap, the fit of the boards is performed with a hammer, the last Board in the row is trimmed to the required size. Each subsequent row is staggered relative to the previous one. On completion of plinth mounted with cable channels.

Under the linoleum should be laid acoustic layer is required because the material itself is very thin. For this suit of plate vibrotek. His butt is placed on the surface of the base, then proclaim joints construction tape. In rooms with an average load can be used as the insulating layer material ISOPLAAT, which in some cases is sold with the linoleum and at the same time serves to protect the flooring and extend its lifetime.