The contents

- General description

- Adjustable lugs on the studs

- Features of the installation log

- The flooring plywood

- The lags in the corners

Thanks to the installation of floor joists can be adjustable to create a flat surface that can be the basis for any floor covering. Under such a design can be place of communication. And thanks to the ease of installation make the floor with adjustable lag may even a person does not possess the skills of the Builder.

General description ↑

The design of adjustable floor consists of a frame and flooring. The space under the joists and between them can be filled with heat and sound insulating materials or be used for laying electric wires. As flooring can be used various materials but most commonly used is plywood. She is laid linoleum or laminate.

As a regulatory element in most cases is the stud where the nut is fixed, serving as a support for the Arab League. As a flooring there may be the following:

- evrodoski;

- gipsovolokonnyh plate;

- cement particle Board.

If the Board is used for wooden flooring, the GVL and DSP are installed before tiling. Feature adjustable floor is the presence of the element with which it is possible to create a perfectly smooth surface. There are ready systems for the creation of such floors, but they can be done independently.

Create floor own hands on the hairpins and corners. Both ways are easy, so the choice can be made in favor of any of them.

Adjustable lugs on the studs ↑

As the lag is applied to dry timber with a section of 50×50, and the supports are studs M6.

For creating the design of the ground floor is drilled a hole in which the anchor is set and adjustable support under the log. So all holes match the holes on the blocks, the drilling can occur through the joists. After installing the studs into the concrete on it is screwed a nut on which is placed the washer. It is necessary to the operation of the tree are not selling a metal element and has not dropped below the desired level.

Not to buy expensive ready-made kits, you can use a standard wedge anchor and the pin. After the supports are securely mounted on concrete, is spitted on them bars. Then you can start to adjust the position of the joists due to the rotation of the lower nut. This level is used, which is located on a wooden element. After installed a few bars, alignment is performed between them. In the end, the bar is fixed PI using a second nut.

Features of the installation log ↑

To start work you should be cleaning the room, not only from debris, but also from any available objects. But before to do this, you should think about what will happen under the adjustable floor. If there will be located in communication, we should advance to make a diagram. If this is not necessary, then the installation is very simple.

But some apartment owners have between the bars insulation or soundproofing. In this case, before the start of work to prepare all the necessary materials.

Everything occurs in several stages:

- First, the wooden bars are arranged parallel to each other at a distance of 30 cm Side elements are not further than 5 cm from the walls. If the distance is greater, the sheets of plywood around the edges will not be able to effectively withstand the load.

- Then drilled holes in the bars and in the base. Usually their diameter is 8 mm. Distance between holes should be about 50 cm If it is smaller, it will not affect the increase in hardness, and excess of this value will contribute to creating a greater load on the tree. To eliminate the possibility of a discrepancy between the holes in the bar and in the floor, you must do them directly through the joists.

- Further, installing the studs and wrap them around the screws on one distance from the concrete. It is important! To the second nut, which will secure variable lags, completely drowned in the material, it is necessary to expand the hole in the top of the bar.

- Then the joists are installed on the supports. The top is screwed a second nut, but since the height is not yet regulated, this element is not twisted to the end.

- To adjust the height of the floor it is best to use a laser level, but in the absence of suitable hydraulic device. Each individual block to be controlled, starting with those nuts which are located at the edges. Then scroll to the other until Ionia is not in contact with the tree. To simplify, you can make a template from scrap bar beforehand adjusting it to the desired height.

- Then there is circumcision of the protruding portions of the pins grinder.

The flooring plywood ↑

If you need to insulate the floor, then use standard materials such as mineral wool and polystyrene. Also at this stage are communication. As the lag can be a distance of from 5 to 20 cm beneath the floor of the conveniently positioned all communication, which can spoil the appearance of the rooms.

The flooring is quite simple. After all, it is only necessary to measure the sheets of material and attach them to the joists with screws. Around the walls is usually left about 12 mm to ensure that the design is not deformed shear some of its elements. The created gap is easy to hide the baseboard. After that, the design of adjustable floor ready for installation of any flooring.

Lags on the corners ↑

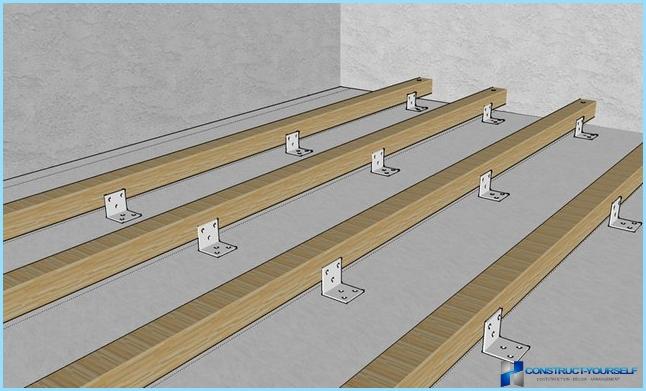

Such structures differ from the previously described variant only in that as a support for the bars are the metal corners. This is the option to choose in cases where the sub floor is fragile and can’t hold the anchor in one position.

Creating a floor is as follows:

- First step is the measurement of the floor level and the selection of corners of different size. If part of a room, the surface is lower than in the other, there is a higher elements.

- This occurs after securing places on the surface with screws. It should be noted that during the installation of the metal elements to make sure that they do not project beyond the line of the floor, as in this case, they have to shorten.

- Further on the established parts of the fixed block. But this is done only after using level.

- To make the design more rigid, there is a fixing of each bar with the other hand.

A further principle of operation is different from what was described earlier. Workers only have to produce insulation and make the flooring of the chosen material.

Features of the device of the floor at the corners ↑

To simplify, the extreme bars should be attached to walls without leaving a gap. Due to rigidity even a slight movement of the parts of the floor not implied.

An even easier solution is to attach the bars around the perimeter of the room. But when installing you need to carefully ensure that they were located at the same level.

Other options adjustable floor ↑

There are specialized support for the Arab League and the tiles that contribute to a more rapid creation of gender. They are usually made in the form of cylindrical elements with a threaded, through which the upper part rises to a different height. The same support can be used for bricks and for tiles, as they can set different vertices.

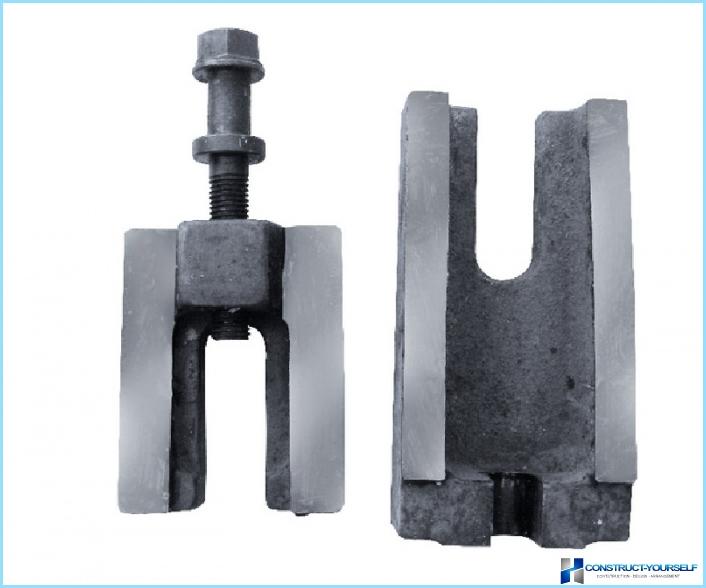

There are also wedge-shaped adjustable support for the Arab League. They are set to produce just enough so as to align the bar only need to place it level and slowly combine 2 of the support underneath. When combined, they create a lag reliable support.

There are other mean of supports for such a floor, so if you want you can choose the most appropriate option. But the most practical solution is to buy studs. This option is more acceptable, as all materials are available and creating such a design is quite simple, if it has all the necessary tools.