The modern market is extremely cruel to the participants and recognizes two things – the reputation or the money. Losing any of these components, you and your business at risk to fly into the pipe, not even noticing the process. The only reliable way of reinsurance – investing in the production of concrete blocks with low manufacturing cost.

Interesting concrete block with low cost ↑

Concrete building blocks have a number of characteristics that can significantly affect the market building block for the private sector. First of all – its low cost. Concrete blocks not used above the third floor, major construction is not interesting, the construction of expensive cottages is also in doubt, but the small private trader could become a prospective client and competitor at the same time.

What affects the profitability and cost of production of concrete block:

- The minimum cost of production at any cost, but not at the expense of the quality of the product, they will become a powerful tool for dumping the first attempts to squeeze into the market of building materials;

- The obvious advantages of concrete block as a building material, is able to provide the buyer of your item higher profits at its further use;

- The presence of super-cheap raw materials for concrete blocks and, consequently, low production cost.

The production of their own hands will allow you to use at the initial stage of personal transportation, utility private premises for production and storage of the first products.

But the manufacture of blocks can be justified in the production of concrete blocks with their hands, if you need to build a small-sized buildings. For the production of wood concrete block for sale, in addition to low cost, you will need precise technology. A quality unit will need to do your own hands at home and on industrial equipment, even the most primitive.

Assessment of the costs and expenses ↑

The technology of producing concrete block is quite simple, the source components are mixed and pressed into a steel form. Preparation-concrete weight and compact easy workable with your hands. Cost side of production of concrete block includes:

- The cost of raw materials;

- The cost of buying or leasing equipment;

- The costs of transportation, handling, storage and drying units.

When the compact wood concrete blocks with their hands each of these points may vary within wide limits, much depends on individual factors that can affect the cost and quality of the unit. If you want you can see the nuances of the online video.

Technology of production of raw materials ↑

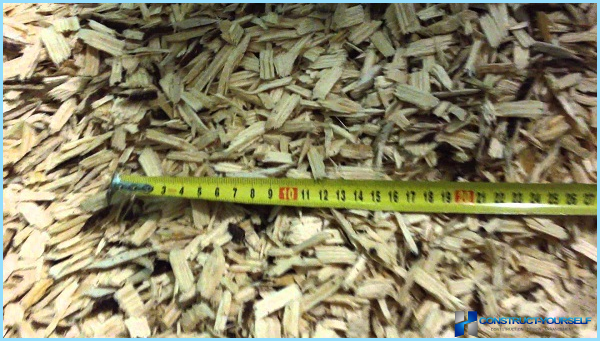

The composition of the concrete block consists of equal mass fractions of cement 400 grade and cut-crushed chips. Per cubic meter of sand will require approximately 320-330 kg of each ingredient. The cement will have to purchase bagged in 50 kg bags. Even if it is more expensive to buy the loose material to the owner to work at home is extremely unprofitable due to high transportation costs. The cost of the required amount of cement will be about 1300 rubles, without shipping costs. With delivery coming out all 1500 rubles.

The purchase of 330 kg of chips – raw cost based on the price at $ 10/cube, about 750рублей, with the transportation – purchase 900-950 RUB the wood filler has a lot of nuances, if the question concerns a permanent purchase of finished crushed filler at the lumber factory, the price can be lower.

Cutting and crushing should be performed only with special equipment or to buy as a finished product.

In addition, you will need about 10 kg of slaked lime and 6 kg of aluminum sulfate. Both drugs are sold in bagged form, Packed in 20 kg 18 $ /kg and 48 rubles/kg, respectively, the cost of drugs – 180 RUB and RUB 288, only 468 rubles, transport costs – all 500.

Water in the amount of 380 liters count at a nominal price of 100 rubles delivery.

Just purchase components for the preparation of a cubic meter of concrete block you will need to spend a little more than 2000 rubles.

The cost of the equipment ↑

In the total cost of expenses the share of expenses associated with the use of equipment for production of wood concrete stone, may be:

- negligible if the underlying mechanisms were leased for a short period of time, even taking into account the rent and depreciation of equipment;

- big enough if all the necessary tooling I had to buy at market prices.

For example, for receiving a concrete mass and the manufacture of blocks with their hands will need a minimum set of equipment, which will include:

- Crusher DM-1 wood pulp in chip material – the cost of the smallest unit will be about 80 thousand. it is Clear that manually crush at 500-700 kg of wood per day is simply unrealistic. It is possible to make a similar homemade unit using profiled cutters, it is quite accessible with their hands, but even in this scenario, a self-made grinder will cost at least 20 thousand rubles;

- Installation for drying the crushed filler cost about 30 thousand rubles., to dispense with pre-drying is possible, but the quality of the concrete block will be «swim».

- Mixer, or better blade mixer for preparation of concrete mixtures and mixing components. Blade option will give the highest quality mixing with a uniform distribution of chips in the composition. The cheapest option GHS-М220 will cost about 60 thousand rubles., a simple mixer will cost 20-25 thousand rubles;

- The vibropress, or set for manual pressing unit. It is better to use a vibration machine, it produces a higher quality of compaction of concrete mass block. The cheapest electric GHS-1 will cost 40 thousand rubles. Set for manual pressing is about the same;

- In addition to the above equipment, production technology involves a critical operation – drying-concrete block at a certain temperature and humidity. Small lot of blocks of suitable shed and plastic film. For regular production, you need a wooden insulated room 30-35 sqm.

A separate line will add to the list at least two two hundred liter barrels for water and dilutions of the components, large capacity for preliminary accumulation before pressing concrete structure and a large number of polypropylene bags for the storage of crushed chips.

In addition to the above items will require a freight truck and a single axle trailer to a passenger car, if there are no opportunities to carry on the truck. The truck can be done by hand, and the cost of equipment for transport to include in the cost of production of construction materials will not. Trailer of inventory of raw materials a month to rent, or to pay for the delivery directly to the seller.

Thus, the cost of the equipment will make about 220 thousand roubles to units of industrial production. If a piece of equipment to make their own hands, the cost of a set составит120-130 thousand rubles.

The cost of electricity ↑

The average total power used by electrical equipment will not exceed 2.5 kW/h, which is quite acceptable for the wiring of a private household or cottage. If you decide to work alone, and everything to do with their hands, the load on the wiring will be even less. The average cost of electricity per cubic meter of arbolit will be about 10 kW/h, which is at the rate of 5 rubles per kWh will amount to 50 rubles, while a significant part of going to work the dryer and crusher.

Summarize ↑

After analyzing the cost of producing concrete block, we can say that the cost of home production depends on many factors.

If you have the opportunity to rent the necessary equipment, paying rent, and depreciation at 10% of value of units per month, the cost of cubic meter of concrete stone will be the production of 50 cubic meters of block per month:

- The cost of raw materials in 2000 R x 50 cubic meters will be equal to 10000 rubles;

- The cost of rent and electricity 22000 rubles 2500 rubles, respectively.

The result is 50 cubic meters of concrete block will cost 125 thousand rubles, or 2,500 rubles per cube unit. If you will have the opportunity to purchase raw materials for crushing of wood chips for the play money or free, will drop the cost by reducing the cost of filler up to 1600-1700rub per mThree.

When you purchase a set of equipment for production of concrete material for the full price, the cost of production of the first batches of concrete stone will increase to an astronomical 5000 RUB per cubic meter. Of course, we are talking about the first batch of goods. If the cost of equipment to distribute for a period of not less than 5 months, which is quite possible when you purchase the equipment on lease or loan, with a 6-month cost of a cubic meter concrete block to fall to 3,200 rubles per cubic meter.

But such a calculation is valid only when you receive high quality concrete stone. For production on a commercial basis it is better to buy ready-made low-tonnage line. This is about 250-270 thousand rubles. How the line is perfectly visible in the video below.

For comparison, the wholesale price in the depths of Russia, in areas rich in forests, is 3700-3900 rubles per cubic meter. Thus, depending on the available resources, even when purchasing machinery, its cost may be lower than the market price of the material.