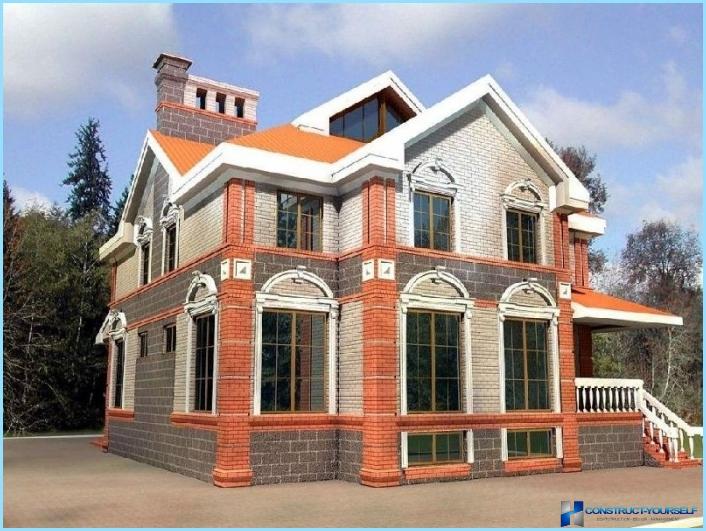

Silicate brick has long been known as «white». But in fact it can be a variety of colors: blue, yellow, orange, red, brown, etc. this material is widely used for construction and decoration of houses. The photo shows how beautiful and original look of the building made of colored bricks. It is worth considering in more detail its properties.

Production ↑

Sand-lime bricks, regardless of color produced by one technology. Mixed quartz sand and lime in the ratio of 9 to 1. If you want to get the colored bricks, such as red or blue, then add a coloring pigment. Without this substance, the products will have a grayish-white color. The mixture is compressed, giving the desired size and shape, and then treated with superheated steam (200°C) and subjected to high pressure (8 to 12 atmospheres). This manufacturing method is called autoclave synthesis.

Strength and other technical characteristics of the product depend on how correctly and precisely observed a manufacturing technology. To improve the quality of the bricks allow special additives-modifiers. So, with their help, we can raise the level of frost resistance or durability.

The types of colored silicate bricks ↑

There are many varieties of silica brick. It is divided into colors (red, black, green), the structure, shape, size, and scope.

In structure there are two varieties of bricks: solid and hollow. In the first case the product has no internal voids, in the second they are present.

By application divided into ordinary, i.e. one from which carry out a laying, and facial. The latter is used for the cladding of houses, buildings.

Size of release:

- Single (size 250h120h65 mm);

- Semi-double (parameters and one half 250x120x88 mm);

- Double (250х120х138 mm), bricks of this size are often called lime stone.

As can be seen, the length and width do not change, only increases the thickness of the products.

Bricks typically have a parallelepiped shape.

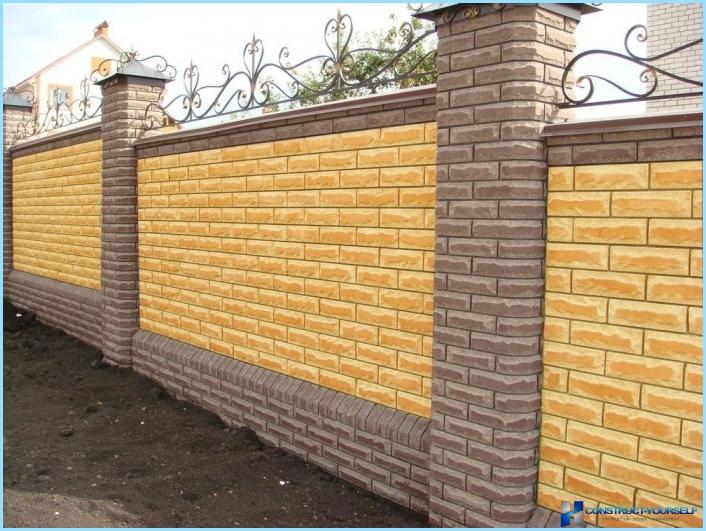

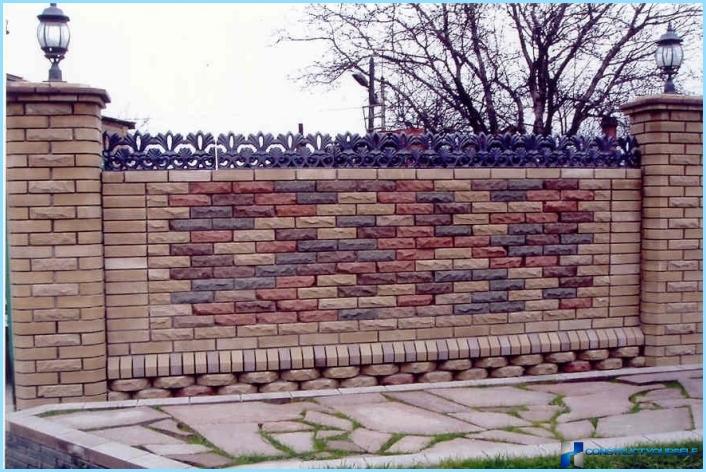

Used in the construction of smooth products and with chipped texture. The latter are used for the cladding work. Embossed brick diversify the architectural appearance of the houses, creates a feeling that masonry made of natural stone.

At the present time are made of materials of different colors, not only white, but also yellow, red, black, blue, green, etc. use the already colored products enhances the building and finishing. After laying the facing color of the bricks does not require any additional work on the beautification of the facade. Of colored material can be spread a certain pattern or design. The photo shows the different designs of houses in red and yellow colors. The inner and outer walls through the use of colored silicate bricks obtained without any additional decorative finishing.

Characteristics ↑

Properties and qualities of the brick to determine its technical characteristics are: strength, frost resistance, thermal conductivity, density, etc. they are also depends on the durability of the material and in what circumstances and for what purposes it can be used.

Strength shows what kind of load can withstand the product. Measured in kg per cmTwo. Denoted by the letter M, for it is written, the figure indicating the permissible load. Now made of silicate bricks of different level of strength from M-75 to M-300. The greatest demand is for the products of this brand M100. It can be considered basic because brick this level of strength can be build buildings up to 5 floors. It is often used in the construction of individual housing in the construction of private houses and cottages, in the construction of various social institutions etc. For construction of buildings of greater height is necessary to use materials of greater strength.

The level of frost resistance – the following parameter. It is denoted by the letter F and shows how many cycles of freezing and thawing is capable of withstanding the product. The higher the number, the more durable the material.

Density can range from 1300 to 2100 kg/mThree. This parameter directly affects the levels of thermal conductivity and insulation.

The thermal conductivity shows how fast will be transferred heat to the colder areas. The higher this value is, the faster will freeze the bricks in the winter. The thermal conductivity of silicate products may be in the range of 0.35-0.7 W/m°C.

Moisture absorption from a silicate brick can not exceed 12%.

The level of heat resistance from sand-lime bricks is not the highest. You can’t use them where they will be heated to 550°C. At higher temperatures they begin to crack and crumble. Therefore it is not recommended to use this material for a laying of furnaces and pipes.

Weight – this is the final option. It can vary greatly depending on the type of product. So, single hollow brick will weigh about 3.5 kg, and full-bodied – up to 5 kg.

Advantages and disadvantages ↑

Sand-lime brick, like any other building material possesses a number of advantages and disadvantages. Of the positive qualities can be noted:

- High level of noise reduction. In a house built from this material, almost inaudible sounds from the street;

- There are products with a low level of thermal conductivity, which helps to maintain a good indoor climate;

- A high level of strength;

- A wide range of colors (from yellow and red to blue and black);

- The availability of products with different texture, which opens up space for design solutions;

- Heat resistance, can withstand heat up to 500°C without compromising its qualities;

- Can be used for masonry interior walls, load-bearing and exterior walls, for cladding of buildings;

- The ability to use colored material for decorative finishing;

- Environmentally friendly and consists of only natural ingredients, in the process of operation does not emit harmful substances into the air, so it can be used for the construction of buildings for any purpose, including for kindergartens, schools and hospitals;

- The colored material can be used for decoration of facades;

- Not combustible, is resistant to combustion, is absolutely fireproof and not susceptible to combustion;

- One of the most affordable building materials in price and prevalence, find a sand-lime brick in any city is not difficult.

However, this material has several drawbacks that limits the scope of its use. Of the minuses note:

- A lot of weight, especially in solid blocks, sand-lime brick is considered one of the heavy construction materials;

- Building high-rise buildings require additional strengthening of the Foundation due to the high weight of the structure;

- A large part of silicate products, has a high level of thermal conductivity, which leads to rapid freezing of the walls in the winter, often buildings are in need of additional insulation;

- Absorbs moisture from the environment;

- The low level of chemical resistance;

- Breaks down quickly in high humidity conditions;

- May be deformed;

- Does not tolerate heating above 600 °C;

- Poor adhesion to the cement slurry.

These disadvantages impose serious limitations on the scope of building material. For example, due to the high level of moisture absorption and instability to moisture sand-lime brick can’t be used when constructing the Foundation. Also it cannot be used in the arrangement of the furnaces, pipes and chimneys. Silicate stones are not used in the construction of baths and rooms with hot shops. On the other hand, due to the ability to maintain the microclimate in the room, decorative and eco-friendliness is one of the best options for housing. The most important thing – to choose the right material.