The contents

- The advantages of bitumen mastic

- Types of bitumen mastic

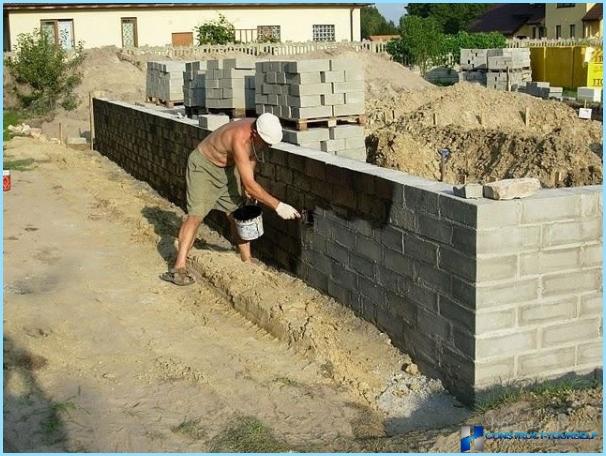

- Treatment Foundation cold bitumen mastic

- Consumption of bitumen mastic

- The order of processing with mastic

Water for several years, wears away even a stone, and concrete and completely invalidates. The house, which is calculated for decades, should have a good waterproofing of the Foundation. Tape or monolithic Foundation contains reinforcement mesh, giving a high resistance to deformation and rupture. Through small pores in the Foundation of the groundwater or meltwater is able to penetrate to the rebar, which leads to corrosion and weakening of the whole Foundation. It will cause cracks in the walls and reduce the lifetime of the whole house.

Bitumastic is a great material for waterproofing that does not allow penetration of water through the pores of the Foundation.

The advantages of bitumen mastic ↑

Bitumen mastic has a number of advantages over other mastics, namely:

- forms a waterproof coating;

- protects from mold and fungi;

- fills small pores and cracks in the Foundation;

- will not crack in the frost;

- has good adhesion to all materials of the Foundation;

- eventually loses elasticity, shock proof;

- can serve as a glue for waterproofing roll or putty joints.

Types of bitumen mastic ↑

According to the method of application of bitumen mastic are:

- cold;

- hot.

For treatment of Foundation with your hands frequently used for cold mastic, as their application does not require special equipment and skills.

Cold mastic is divided into two types:

- water-based;

- polyester based — pure or bitumen with added polymers.

Polyester bitumen polymer mastic is ideal for working in severe cold (down to -40°C), unless the material is of good quality from a trusted manufacturer.

The properties of mastic are of two types:

- single component — ready to use, you only need to mix;

- a two component — have longer service life and storage, before the application requires you to connect components quickly seize, therefore, need to be applied immediately after mixing.

Hot mastics are used less frequently when you need to create a security Foundation in especially harsh conditions. Before applying the substance is heated to 300°C, therefore it is necessary strictly to observe safety precautions. If you have no experience working with hot mastic and the right tool, it is better to use cold.

Treatment Foundation cold bitumen mastic ↑

Equipment and material to work with:

- roller;

- brush;

- spatula;

- equipment if you plan to apply the mastic coating;

- gloves;

- the solvent for rinsing in contact with mastic on the skin.

Obmazochnoy waterproofing mastic applicable in malovlazhnyh and draining soils where the water table is 1.5-2 m below the floor level in the basement. At the hydrostatic pressure up to 2 m is used, bituminous material, up to 5 m of bitumen — polymer. The material obtained by melting solid bitumen is cheaper, but significantly inferior in durability specifically designed composition.

Consumption of bitumen mastic ↑

The material is applied in 2-4 layers, depending on external conditions. Consumption depends not only on the size of the treated surface, but also the material Foundation of both the manufacturer and the quality of the postmark 300-900 g/mTwo surface. The thickness of the coating of waterproofing to 3 mm, for gluing of roll only one layer in 1 mm Approximate consumption postmark is indicated on the container, for ease of calculation of the required quantity.

The thickness of the waterproofing layer depends on the depth of the Foundation:

- if the depth of up to 3M layer of mastic 2 mm;

- depth of 3-5 m layer of 2-4 mm.

The order of processing with mastic ↑

Surface preparation of the Foundation. ↑

- All chips, significant cracks and sinks from bubbles in the concrete (more than 2mm wide) are sealed remotable, the sharp edges of the spread.

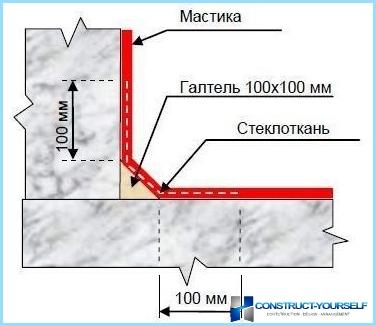

- To provide a smoother transition between planes, corners rounded or cut at a bevel: the more gentle the curve, the more evenly it will layer on transitions. To round joints on the inside of the corner, use the fillet.

- Excess moisture will cause blistering and delamination of the insulation layer. The humidity of the coated surface is not more than 4 % if the water-based mastic — 8 %, but not more. To check the humidity, you can put it on the surface of the Foundation plastic sheeting 1×1 m, having sustained up to 24 h If the film is not condensed, then the moisture content for satisfactory coverage.

- For better adhesion of the mastic to the Foundation is treated with bitumen primer — a primer that is appropriate for the applicable type of mastic. The primer is applied in one layer, cracks in the ground and pits filled with remontowa in two layers. The primer is applied by brush or roller. Upon drying of the primer, you can begin applying the membrane waterproofing.

Application of asphalt mastic. ↑

Apply mastic can be roller, brush, trowel or sprayed using special equipment (only for external works). The layers are applied by roller, brush, trowel or watering the parallel strips without any gaps from the bottom up.

Reinforcement of waterproofing. ↑

Reinforced waterproofing less susceptible to stretching upon expansion of the cracks in the Foundation, more durable.

Reinforcing materials are fiberglass, and fiberglass. Fiberglass roller tightly rolled in the first layer coating, under it should be free of cavities. When the layer with fiberglass underneath it hardens, apply a second. The overlap of adjacent strips of fiberglass on each other — at least 1 cm.

Basement waterproofing mastic is shown in the video:

The choice of type and brand of mastic ↑

Factors considered in the choice of mastic:

- the temperature at which you plan to work;

- waterproofing external or internal surface of the Foundation;

- the surface area and scheduled work time;

- the load on the waterproofing during operation;

- allowable costs for the materials.

The most common type of coating material — conventional bituminous mastic on the organic solvent used in sub-zero temperatures. The daubing is performed by brush, roller or spatula, and requires no special skills. The material is suitable for most cases.

Bitumen-polymer mastic is characterized by high elasticity, adhesion and temperature range of use, the cost of such mastic above.

Do not skimp on the quality of the material. A good paste can be determined without opening the container. It is lighter than water, despite the density and variety of different species. Full 5 litre container should not weigh more than 5 kg.

If this is not it is fake, ordinary bitumen is diluted with solvent or diesel fuel. Substandard waterproofing will last a few years, then cracks and crumbles.

Popular manufacturers ↑

Aquamist ↑

- the average consumption per layer — 1 kg/mTwo;

- drying time is about 24 h, the lower the temperature, the longer drying time;

- permissible operating temperature is from -10 to +40° C;

- before backfilling of Foundation waterproofing ready pasted plates made of foamed polystyrene;

- do not use if poor ventilation, near open flames in residential areas;

- after contact with skin, wash with solvent;

- storage temperature — -20 to +30° C, do not store in direct sunlight;

- shelf life — 18 months.

TECHNONICOL № 24 ↑

- bituminous mastic containing additives, mineral fillers and solvent;

- purpose waterproofing of concrete, reinforced concrete, wood and other structures;

- consumption per one layer — up to 1 kg/mTwo;

- operating temperature — from -20 to +40° C; at temperatures of below +5° C pre-soak in warm not less than 24 hours;

- curing time — up to 24 h in normal conditions;

- do not use near open fire, bad ventilation, avoid contact with the skin;

- storage temperature — -20 to +30° C, store in a dry, dark place;

- shelf life — 18 months.

Don’t use cheap materials. To pay a premium for products from great producers much better than a couple of years to do the second treatment.