To someone who has never dealt with cement, it is difficult to understand what is a concrete solution and how to prepare. But even experienced builders are not always aware of all the subtleties of working with him. In this article we will describe not only the process of making concrete solution, but the correct choice of its components.

Prepare concrete mix for the pouring of the Foundation, small concrete structures, tracks easy. Knead it in any old tub, trough, box or downed wooden shield. In small quantities the process can be mechanized using a power drill with special attachments. If concrete need a lot, you will have to use a normal shovel, small garden fork, hoe or other suitable to the occasion device. But before you start kneading, you should choose high-quality cement, gravel and sand.

Components of concrete ↑

The main component of cement ↑

The strength of our solution will be determined primarily by the quality of cement, therefore, its correct choice is especially important. Factories producing such products, many in Russia and they sell it usually in the neighboring areas. So the focus is not so much on the manufacturer how much the appearance of cement.

Be sure to pay attention to the date of manufacture over time its activity decreases sharply. Fresh cement compression in the fist turns into a ball, and wakes up easily between your fingers. Especially quickly loses its properties when stored quality product fine grinding.

When it fake used dolomite dust, mineral powder, fly ash and other fillers. When they are mixed, of course, concrete is not only slower to catch, but after hardening is not strong enough:

- color quality cement powder darker;

- the solution of it is well sticky and sets up fast;

- color of the dried concrete outside a little brighter, but if you hit the area, its inner surface is dark;

- after complete drying (one month later) in the finished concrete is very difficult to hammer a nail.

The strength of the mortar depends on the cement type. When naming the figures after the letter M, means the ability to withstand a 1 CC That is cement M200 can withstand a load of 500 kg per cubic centimeter. Naturally, the higher the grade, the stronger will be the concrete. A special brand of strength 600-700 used so infrequently that when working with complex or multi-tiered designs it is better to use cement of mark M500.

Letter designations following the numbers, denote the presence of additives. For example, product brand M500 B – fast setting, vrts – waterproof BC – white for the decoration. Marking БЦ20 will mean that it contains 20% of the brightening additives. The most important Supplement for us – PL – makes it frost resistant, so it is desirable to use for street work, especially in the conditions of Siberia and the North.

During long-term storage of the cement powder is compressed, compacted and its specific weight increases. So if you bought it in advance, be sure to store it in a dry, protected from drafts place. It is recommended to wrap paper bags plastic film. Note that after six months of storage the quality will be reduced not less than one-third.

Which sand is better ↑

The best sand – river. It is washed with water and, unlike the career, does not contain impurities. When you work in the winter better to use the river, completely free from clay inclusions. At subzero temperatures the clumps don’t dissolve in water even after prolonged stirring, and the concrete surface will be uneven.

The choice of crushed stone ↑

Dolomity, crushed limestone is most often used to create small, lightweight structures, the quality of which is not subject to increased demands. Gravel or granite material is more durable and able to withstand the lowest temperatures.

Prepare a solution of ^ the

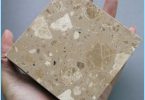

Proportions of the mixture depends directly on the concrete which brand (that is some strength) we will need. The most common proportion when using the brand M500 – 1:2:3 (i.e. you need a part of cement, two of sand and three of crushed stone). The higher the grade, the less out of cement. Therefore, the aspect ratio for М350 will have others. In any case, the ratio of water and cement should not be more than 0.5.

Table – Concrete made of cement M500 ↑

| The required grade of concrete | The proportions of cement, sand and gravel (CHPs), kg | Concrete output of 10 liters cement |

| One hundred | 1×4,6×7,0 | Seventy eight |

| Two hundred | 1H2,8×4,8 | Fifty four |

| Three hundred | 1×1,9×3,7 | Forty one |

| Four hundred | 1×1,2×2,7 | Thirty one |

| Four hundred fifty | 1H1,1H2,5 | Twenty nine |

For production of garden paths enough M200 concrete and fine aggregates (gravel or crushed stone). Good and solid asphalt obtained from the grades of 300 and above. For the Foundation, of course, need a more durable design. The ideal option would be the M500. On average, one cubic meter of the mixture will need 6-7 bags of cement M500.

To avoid the formation of lumps repromachine, water is added only after mixing of cement with sand. The mix for plastering must be sifted through a sieve with cell size of 5 mm for ordinary work it is possible to use larger cells.

In the cold season is clean, with no major impurities of water, preferably a little warm. To avoid the formation of lumps, first in the prepared capacity is filled with a mixture of sand and cement and then water is added.

When solidification is bad the solution formed a fragile construction, prone to fracture.

The whole process of making concrete and mortar, you can clearly see by reviewing the following video: