The contents

From the beginning the appearance of the pellets they were not considered as a serious alternative solution to fuel problems. Rather, it was an attempt to find a rational use for the waste of numerous sawmills and the furniture industry. Then use as ballast, filler cat litter and insulation. Sawdust and wood dust was a cheap raw material, but is very inconvenient in transportation and processing. By analogy with the compressed coal dust, sawdust tried to handle the pressure and the result was pellets, but with low strength characteristics.

It was assumed that after delivery to the place of processing of granules of pellets will rasplyvetsya in cereals, and further are well developed technological cycle. In the mid-80s of the last century fuel crisis forced the country with great reserves of timber, to find a way to reduce the cost of fossil fuels. Wood pellets pellets have a chance to become a full fuel and to find its niche in the market.

Modern pellets for heating ↑

Quickly enough, experts have found a way to increase strength and fuel characteristics, the use of a new inexpensive and environmentally friendly fuel began to gain momentum as alternatives to coal and gas. Modern fuel pellets are hard and durable granules with a diameter of 5-8mm and lengths up to 40mm, with energy characteristics similar to hard wood, which greatly simplifies their storage and use.

The fuel pellets have shown many interesting properties, appreciated by the consumer:

- Ease of storage without loss of quality and fuel efficiency;

- High environmental friendliness and lack of harmful components in the combustion products;

- Increased in comparison with a wood-fired fuel calorific value;

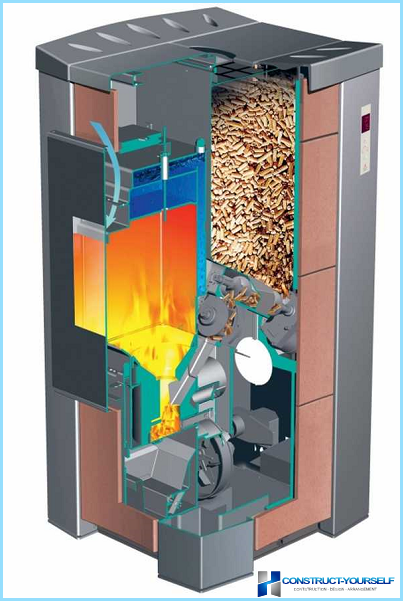

- The possibility of automation and mechanization of processes of loading of the furnace of boilers for pellets.

Pellet production ↑

Through the use of waste agricultural and forestry production do pellets fuel pellets are obtained environmentally friendly, respectively, the characteristics of the ash and combustion products look very good and do not pose a risk for domestic consumers. An important contribution to this important feature adds the use of specific equipment for the production of pellets. Often a compact but powerful press equipment allows to establish the use of waste directly at the place of receipt. For example, a sawmill or a wood processing plant plant.

What «crushed» pellets pellets ↑

Another remarkable characteristic of the fuel pellets is very broad raw materials base of production. For the manufacture of pellets with high performance use at least 80% coniferous varieties of sawdust and wood chips. The rest can be filled with husks or cobs of corn, sunflower. All suitable, as a filler, but subject to the availability in the composition of the pellets of the coniferous component.

The only conifer due to high content of the wood hemicellulose, under the influence of temperature and high pressure beginning to behave like a solid glue – spread on the volume and solder all the components in a solid granule.

Characteristics of calorific value of fuel pellets of relatively low – 18-19 MJ/kg Is about one-third of the heat of combustion of liquid fuel stove or cooking gas. Largely, the calorific value of the fuel depends on the use of raw materials, the denser and heavier the wood, the higher the capacity and strength of granules.

Extrusion lines for the production of pellets ↑

On the market there are a lot of suggestions of various lines and equipment used to produce pellets. From huge multi-ton lines to the plants for personal use, of a few tens of kilograms. Many of them are so simple that using design a technical solution, you can make a pellet mill to produce pellets with your hands with good features.

Standard device powerful installation is a construction of two thick-walled steel drums, mounted on a strong steel frame. The drums have a common line of contact and rotate in opposite directions. On the surface of the working drums are apertures, through which are extruded and formed themselves granules.

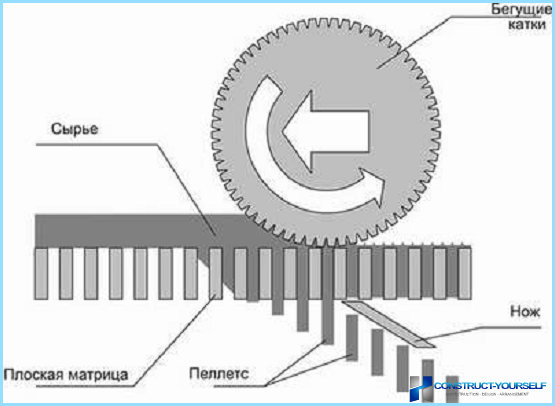

In a more simple and affordable version of the granulator allowed two runners roller rolling on the surface of the perforated disk. Runners rotate with the gear motor, and using your weight and clamping force, raw material is extruded through the holes in the disk, like the production of pasta.

A small design will allow you to get from 30 to 100 kg of pellets per day, which will allow you to use the available cheap raw materials to produce pellets fuel pellets with their hands in winter in sufficient quantity. Characteristics of such fuel is slightly worse than the pellets in commercial production, but only in the strength of the granules. They burn worse.

How is the production of pellets ↑

This is a very good business, but it requires the purchase of quality equipment for pellets, granules proposals on the market more demand, and the mediocre fuel characteristics there is a huge risk of burn. To compete with powerful complexes is possible only by reducing costs and unproductive expenses.

In industrial technologies for production of pellets laid along the following sequence of operations:

- The raw material is ground into flour and carefully dried to a moisture content of not more than 10%;

- In the raw material necessarily use a certain amount of additives, anti-caking and ulucami fluidity of powder;

- Heated to a temperature of not more than 200onWith and 2 5 tons of pellets is extruded through a die;

- Special knife cuts the extruded «spaghetti» to obtain the necessary dimensional characteristics;

- Sometimes in the production allow the use of overheating the pellets for hardening the surface of the granules, it greatly improves the strength characteristics of the granules.

They are not recommended for use in domestic boilers, produced for use in boilers and units thermo-generated installations.

The technique of using pellets for heating ↑

From one cubic meter of raw material get 1000 DMThree the pellet fuel. A rough calculation will show that to heat the 100 mTwo dwelling requires the use of 10kW heating installation, consuming in average 3 kg of fuel per hour.

Characteristic cost of heating with pellets ↑

The average daily rate of up to 60 kg within 6 months you will spend about 10 tons of pellets, when srednepotolochnymi price of 3600 rubles per tonne will be at least 36тыс. For comparison, heating with coal briquettes or coal will cost about 20-22тыс.RUB, when using gas heating will rise in price by 15%. Calorific characteristics of the pellets are clearly losing.

In addition, for efficient burning and heat use requires a special pellet boiler, with fittings and control systems it will cost at least 1300-1400 dollars. In fact, it is the price of a two-year supply of pellets.

On the wave of popularity, many Western producers realized to occupy a niche boilers, using fuel pellets and more advanced specifications. Most popular now become boilers-fireplaces, allowing its installation even in apartments high-rises.

Summary ↑

Simple arithmetic addition and calculation do not reflect the actual situation. The popularity of this unusual fuel due to a number of circumstances.

First, granules find increased use and application in the countries with huge reserves of forests – Finland, Austria, Germany. There is not only the cost is lower, but the characteristics above due to more high-energy wood.

Secondly, the use of pellets in the EU is still cheaper gas, fossil solid fuel or oil due to high consumer prices;

Third, practically all production of pellets is dated and subsidized as innovative environmental activities. Moreover, the financial stimulated by the use of fuels with high environmental performance.