The contents

A particularly important stage in the construction of concrete swimming pool – waterproofing of the structure. Mistakes made while waterproofing works, can seriously shorten the life of the whole structure, lead to the need for permanent repair activities, and even make further use of the pool impossible.

Why do we need internal and external waterproofing? ↑

First, what are the functional features of waterproofing. Its task is to prevent the ingress of moisture inside and outside of the pool in the inner layers of material construction, because a hairline fracture of 3 mm is fraught with the destruction of the concrete bowl. There are external and internal waterproofing. External protects the construction against ground water and flood water, domestic – water that fills the pool, as well as from chemical compounds (disinfectants) used for water purification. Harmless to humans, the exterminator has a destructive effect on the concrete structure.

Quality requirements of waterproofing the pool:

- Strength and durability.

- Resistance to external influences.

- Great elasticity.

- High adhesion.

Perfect waterproofing must possess all the specified properties, forming a solid and seamless layer on the surface of the pool.

External waterproofing ↑

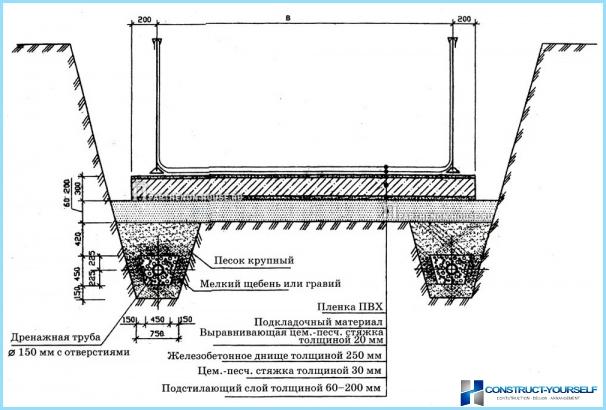

External waterproofing requirements, similar to waterproofing basements. The difference lies in the parameters of shrinkage and changes in geometry of the structure of the pool under the influence of a large volume of water and the arising dynamic loads.

Runs the external waterproofing of the pool using the following materials:

- Clay castle.

- Gidrostekloizol.

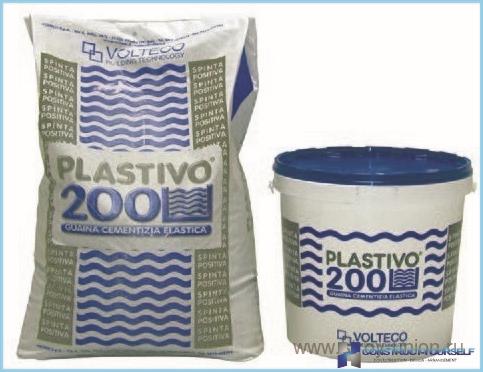

- Obmazochnoy waterproofing, for example, a two-component mixture of PLASTOVO 200. The first component of the mixture PLASTOVO 200 consists of fine-grained aggregates, special additives and cement binder. The second component is an aqueous dispersion of acrylic polymers. The result of the mixing is homogeneous solution which is in two layers applied to the outer surface of the pool. The resulting after curing of the composition elastic layer does not pass carbon dioxide, sulphur dioxide, chlorides and sulfates, can withstand a pressure of 1.5 ATM.

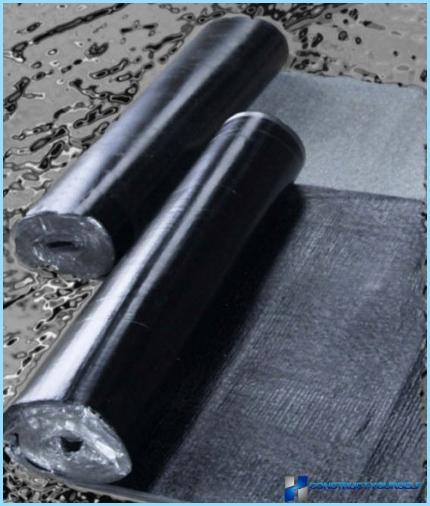

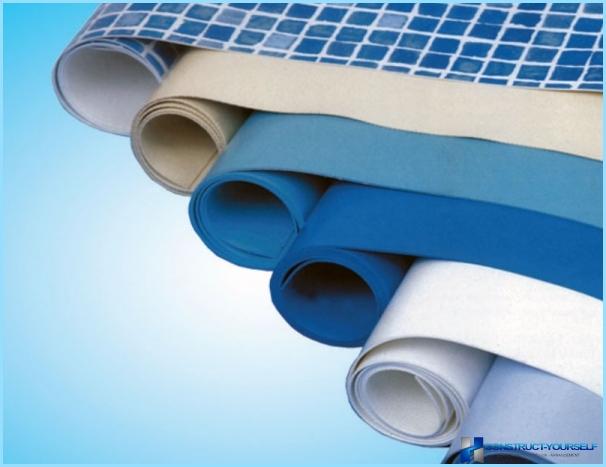

- Membrane and films. Membrane materials and plastic films tested by years of operation and proven reliability. The first are expensive and their use requires high qualification of specialists, the second, on the contrary, the affordable. Their common problem – any damage will require replacement of the entire material.

- Mixture of penetrating. Mixtures penetrating (Izofast, Tenebit-M, Infiltro, Penetron) are plasticizers, sand, and cement. When applying the mixture on the concrete surface, it penetrates into the structure of the material and fills the micropores and cracks.

- Injection waterproofing. Is mostly imported polyurethane formulations for insulation of seams and cracks. In the concrete, holes are drilled and high pressure injected polyurethane composition. When interacting with water, the composition expands and fills in all the problem areas.

In the construction of swimming pools often used the combination of various materials, which increases the reliability of the waterproofing layer. For example, the walls coated with bitumen mastic, with subsequent packing of rolls of waterproof membrane. The seams between rolls of welded construction dryer.

The use of modern high-performance penetrating and injecting compositions to a certain extent limited by their high cost, and the cost of their application.

The most affordable and proven method is the device of a clay castle. The soil at the installation location of the pool was chosen in the pit poured and tamped clay. Clay castle used in combination with other waterproofing materials.

External waterproofing is only applied to outdoor pools. For pools in areas it is not required.

Internal waterproofing ↑

The bowl of the pool is a monolithic reinforced concrete structure, and the penetration of moisture into the micropores of concrete will inevitably lead to corrosion of the reinforcing frame and reduce the strength of the whole Cup. Trapped in the micropores of the moisture under the influence of negative temperatures will begin to expand and form cracks. The mass of water in the pool constantly has static and intermittently dynamic pressure on the structure, speeding up a negative process in the material of the bowl. To counter this and have internal waterproofing.

For device internal waterproofing concrete bowl is cleaned of dust and debris, checked for cracks and seams that are processed by materials to seal the seams. To seal the joint sealing tape is used.

The surface of the bowl is levelled by plastering the walls with waterproof compounds for swimming pools, to align bottom use self-leveling mixture. All surfaces should be primed with primer (Gruntofol, Aquadur).

Then select the type of waterproofing based on the capabilities of the customer:

- Used for gluing materials based on polymerized bitumen (Stekloizol, Stekloplast, Robitics). They are placed in hot condition.

- For waterproofing apply mastic type Cemizol 2EP, Idrosilex Pronto, Ceresit, Penetron. Its composition is a polymer putty that creates an elastic layer on the surface of the bowl.

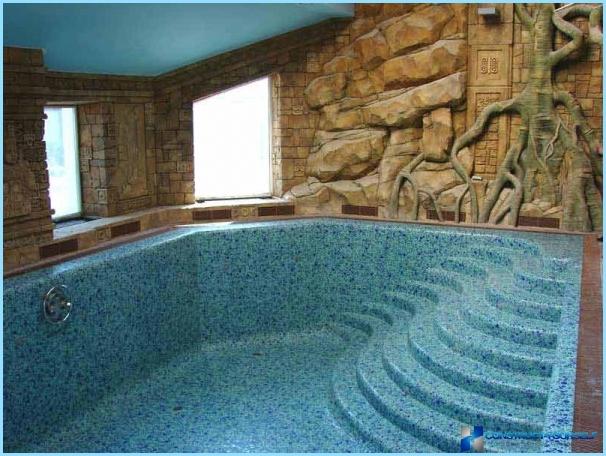

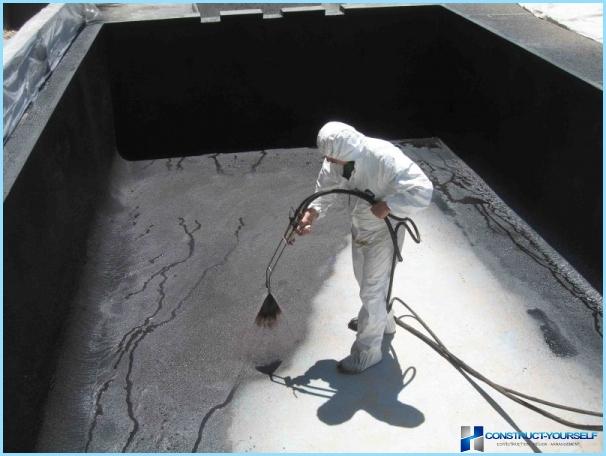

- Waterproofing of the pool possible to make a bitumen-polymer mastic, which is called liquid rubber. Sprayed liquid rubber compressor (for large volumes of work) or applied by roller or brush. This mastic has high adhesion (adhesion) with the surface of the pool and creates a durable, flexible film with excellent waterproofing properties. Liquid rubber combines the qualities of liquid waterproofing membranes and PVC. On the layer, you can put a mosaic or tile. Now manufacturers have mastered the production of liquid rubber of different colors, which allows us not to lay the final layer with and without decoration. Touch liquid rubber so pleasant as membrane materials. If you work on application of this polymer-bitumen mastic performs the specialist team (usually of 3 people), the change they can handle up to 1000 m?.

- The use of membranes allows you to combine waterproofing and decorative functions. The discs are available that mimic marble, mosaic and other finishing materials. The disadvantages of this material include relatively high cost, the complexity of the application process. First, a special liquid is processed angles and lines of adjoining surfaces of the bowl, then on these places is glued to a reinforcing fabric, and apply again the liquid. After drying, a bead of fluid is applied to the whole inner area of the pool. Fluids laying reinforced fabric, carefully distributed at the bottom and the walls, and again covered with a special liquid. After drying, all the layers form a single continuous membrane with excellent waterproofing properties. Membrane require strict observance of technology of installation and monitoring of the safety of the material.

- The most affordable material for waterproofing of the pool – PVC film. Usually such films are used in budget pools. After the film spread out, the seams are welded construction dryer. Speed stacking this material is high. The disadvantage is a very small selection of colours of material and the inability to make a film without seams that will be visible in the pool.

The work on waterproofing be sure to apply sealing cords, with the aim of sealing joints and seams, for example, polymeric harness Penebar. The polymer when in contact with water swells and seals the crack or seam. After grouting cords, they are treated with penetrating waterproofing composition.

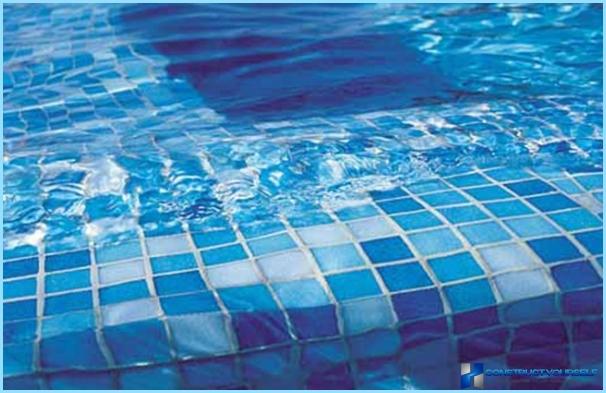

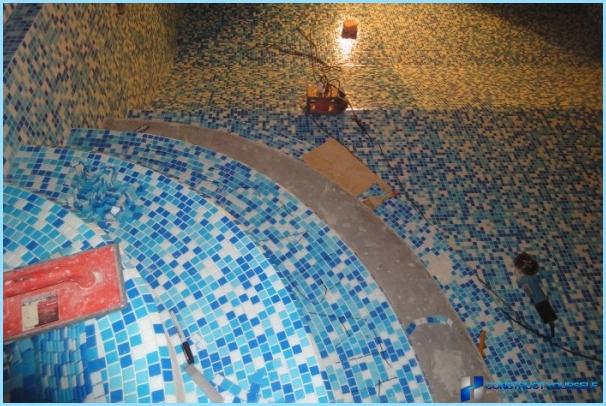

After execution of waterproofing works on the walls and bottom of a stack or mosaic tile. In order that the water, once through the tile seams, did not lead to delamination of the tile, use a special insulating grout. Insulating grout is a polymer or epoxy. Using a rubber spatula press them into the space between the tiles. Immediately after applying the tiles should be wiped to the remains of the composition congeals on the surface.

Before starting work on waterproofing of the basin are recommended to assess their capabilities and strength. Have to perform a very important stage, and the failure of technology, carelessness, inattention may prove to be very expensive. Choose the type of waterproofing that you will be able to cope on their own, while the job efficiently.