The contents

In the design of any interior critical point is the correct placement of accents. This ratio is achieved through the use of various items and accessories. But their placement is necessary to use various items of furniture, fixture, particularly if the issue relates to the walls. One of the best solutions in this case are wooden shelves which quite on forces to make even an inexperienced home technician. About what they are like combined with the interior of what is needed to create a coherent composition will be discussed further.

Types of shelving ↑

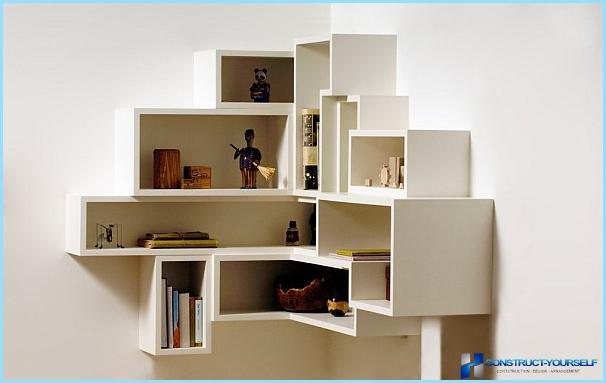

From the point of view of furniture industry, technology in General, the shelf is a product that is designed to accommodate storage items and accessories interior. Most often it is not the front, and sometimes rear, side wooden walls. Are made of different, including scrap materials. But as the theme of the article covers the traditional wooden shelves on the wall, then the classification will consider them from the point of view of form, method of fixation:

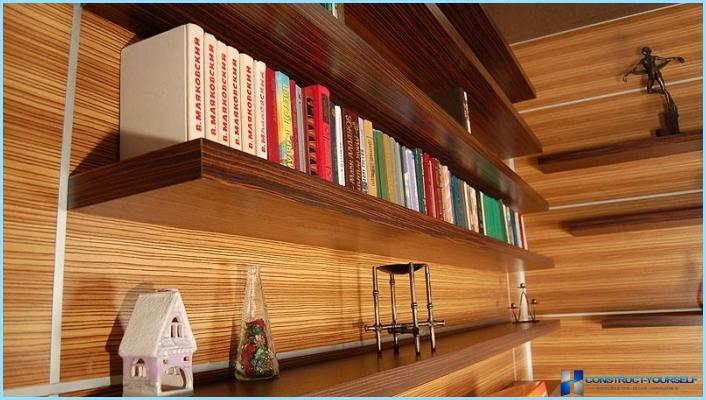

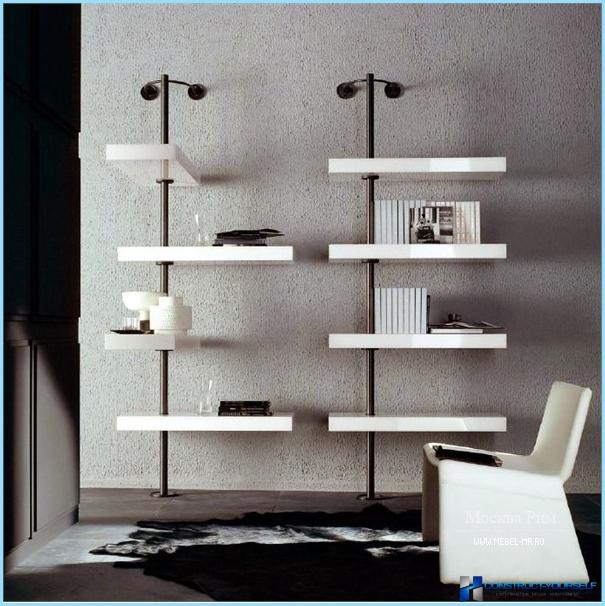

- Classic. It is diverse in terms of spatial layout wooden products, unifying factor which serves as the method and location of attachment. They are usually placed on the wall surface, in combination with the other elements of furniture (sofas, chairs, tables) from the point of view of ergonomics or harmony. With the installation typically use a shelf support for wooden shelves on the wall or other fixture;

- Pendant. This group of wood products is in some way analogous to the previous one, but the fastener is effected by flexible elements (ropes, belts, chains). Also often flexible connection used in stacked structures to interconnect the individual shelves;

- Corner. From the previous corner shelf wall wood differs in that it attaches not to one but to two adjacent walls. Can be internal or external, depending on what the angle is formed.

The ways of fixing all these wooden products can be divided into two large groups:

- Wall. As you can tell by the name, the shelves are attached directly to the wall or to the ceiling through special elements and accessories. All three of the previously mentioned class can belong to this group;

- Outdoor. These wooden pieces of furniture usually have the furniture legs. Mounted on the floor close to the wall. This category can be attributed only to classical or corner shelves, due to their structural features.

In addition, if the manufacture of the wood compositions are used elements that restrict free access to content, all shelves can be divided into open and closed. In the latter case might apply, for example, glass or plastic doors for shelves.

Possible fasteners ↑

Whether it’s outdoor or classic wall shelf, install, and lock it on the place in different ways:

- Shelf support for wooden shelves. A classic option for single – and mnogobrojnih compositions. Hardware also serves a decorative, functional role, attached to the wall and to the construction;

- Loop. Another popular, common option. The gist of it is that on the back side of the flange is a mounting loop (fixed or adjustable), which is attached with dowels to the wall or hung on a special mounting bracket;

- Hidden pins. One embodiment of the shelf support shaped pin of circular cross section, which is attached directly to the wall. The regiment itself has corresponding recesses for installation;

- Stand. This option is suitable more for outdoor wood compositions. Can be run as a separate, single legs or whole frame structures.

In General, if you analyze these options, they can be divided into open and hidden. The choice in favor of one or the other discusses the design of interior spaces.

Necessary tools ↑

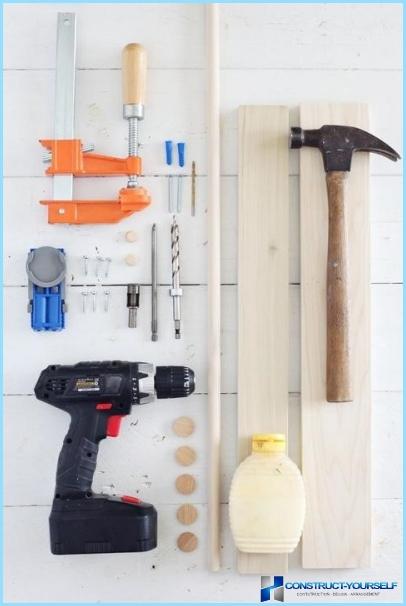

To make wooden shelves with your own hands is not as difficult as it might seem at first glance. To treat this event as a simple scratching of the head is not necessary. A little ingenuity is needed here, but without the tools, it will not help to materialize ideas. To create shelves is the most useful:

- Sundries. Depending on how complex will be the wooden structure, you may need screws, screws, nails and of course the dowels for mounting on the wall;

- Accessories. In fact – it is nothing like fixing elements, by which the shelf will be hung on the wall or installed on the floor (hinges, brackets, shelf support, cables, racks);

- Consumable. This wooden Board is the main part of any shelf;

- Tool for working with hardware. Here you can use a manual (screwdriver), automated tools (drills, screwdrivers) to which the kit will have to pick up the drill head (bits) for wood surfaces;

- A tool for cutting. Here again you can use a manual (saw, hacksaw, abrasives) and storage options (jigsaws, routers, orbital sander);

- Measuring and auxiliary tools. Rule «measure twice, cut once» here is applicable in full. To achieve this we often use tape measures, rulers, t-squares, levels, clamps, construction pencils.

When the tools and materials assembled, it’s time to begin the process of making shelves.

Preparing ↑

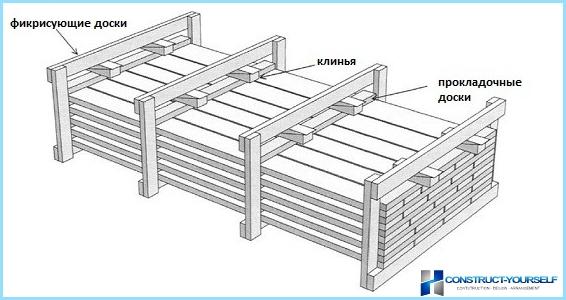

This is the initial stage which involves selection and initial processing of the wood for shelves. Selected planks, usually of pine or fir, should be perfectly smooth. They should be no cracks, voids, branches, lesions of mold and other defects that may affect the future integrity of the shelf.

Humidity should also be minimal. Otherwise, the Board will continue to dry out already in the finished design, which will affect the form, structure, strength. The drying process takes place more efficiently if pieces of wood placed in piles with intermediate layers.

Boards for shelves, which are selected in the job, pre-polished. Is carried out in stages, using different abrasives. Normally, the initial processing occurs sandpaper number 40. If the roughness is insufficient, use smaller sizes No. 80…One hundred twenty.

If in the process of sanding will show up small and medium-sized defects, they can be repaired using a special putty for wood surfaces.

Markup and processing ↑

Polished billet for shelf space with the aid of a measuring tool. Originally cut dimensional details in accordance with the drawings. It is best to use for this purpose, jigsaws, since the cut surface is even and smooth.

After that there is a markup and processing areas for future hardware. You will need to use drill or screwdriver with the appropriate bit set. Perhaps it will have to use the router or a specific cutting tool, but it all depends on which way fastener, like most bookshelf composition.

The choice of size is determined by the functions of the shelf and dimensions placed on it items and accessories. The thickness of each Board can be selected depending on the intended load. For example, Shoe rack wooden, is one of the most sought after furniture products in the hallway of any home or apartment. Usually it is a multi-tier structure, the dimensions of which are selected according to the following principle:

- Depth – the maximum length of the Shoe, which will stand on a shelf, and allowance (in average from 25 to 30 cm);

- Height – in this case, refers to the distance between adjacent shelves vertically, which is subject to the allowance should reflect the height of the used shoes (usually of the order of 20…25 cm);

- Width – the size of the Board is determined based on the free placement of several pairs of shoes, or rather, the width of individual pairs. Typically, the shelf size is referenced to the standard furniture (600, 800, 1000, etc.).

After all wooden parts are cut to size, and the geometry brought up to appropriate drawings or the plan designer shelves should be treated with a protective and coloring compounds.

Cusp on the kitchen example ↑

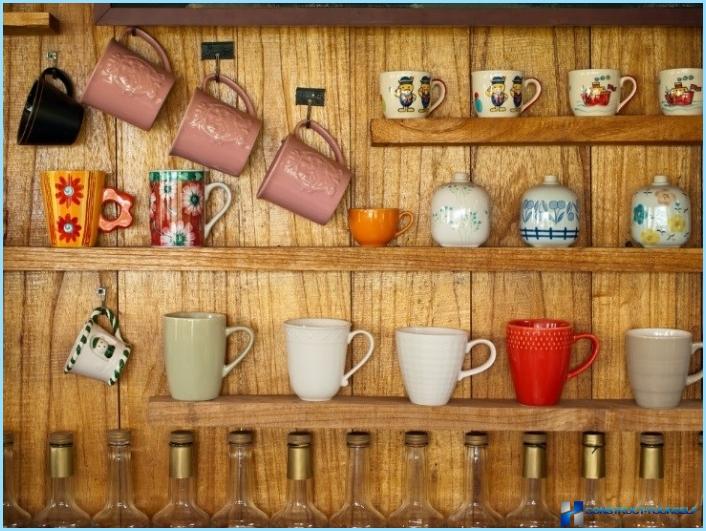

As in the previous sections, we have to admit that the process of Assembly of finished products depends on design, fastening is selected and what is the purpose of the shelf at all. Based on the operating conditions, wooden shelves for dishes are usually used for placing the various utensils and containers with food, usually loose. In the example, consider the simple l-shaped shelf that will simultaneously serve as a support for cans and «hanger» for mugs.

It is obvious that the whole construction consists of two wooden boards: on the horizontal will be placed in jars with food, and in the vertical provides a loop for hanging mugs and the mounting holes. Sizes are selected in the first case, taking into account the diameter of the cans and their total weight, and the second based on the size of the eyelets mugs.

After cutting to size, in a vertical plate drilled the holes for the pegs and for connection with a horizontal flange (have to use a special angular conductor). After that, the two boards are joined together with screws.

In the prepared holes hammered wooden pegs. Inside pre-applied glue (PVA). With its help, attach the decorative circular limiters. They can screw screws, but in this case you will have to use a decorative cap.

The finished shelf is covered with a lacquer or enamel and after drying is screwed to the wall with dowels. It is necessarily controlled by its horizontal position.

In a similar way and made a wood shelf for the fireplace, but its role is more decorative and the elevation of the upper part of the furnace.