The contents

- Mechanized plaster: what it is

- The main advantages and disadvantages

- The technology of mechanized plaster walls

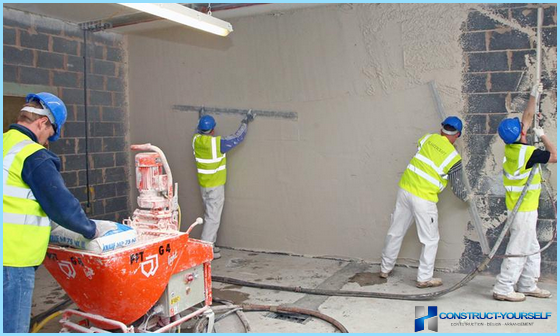

Automation firmly established in all spheres of human life, I do not pass it a party, and construction. The past half century, everything is done to facilitate and reduce manual labor. We all know that plaster walls is a fairly difficult process. It is not surprising that the plaster walls mechanized gained enormous popularity, because more than 50% of all work performed by a special mechanized equipment.

Mechanized plaster: what’s that ↑

In this innovative method of alignment of walls, except special plaster mixtures, used mechanized plaster station. Plaster station is mechanized equipment designed to manufacture high-quality solution and its uniform application on the wall.

After the use of mechanized equipment are reduced to a minimum all subsequent work on puttying walls, because the coating is perfectly smooth and even.

The main advantages and disadvantages ↑

The main advantage of the plaster walls in a mechanized way is process automation. However, this method has other advantages:

- Savings on building materials. Plaster mix while stirring mechanically, and is saturated with air, and this leads to the fact that its volume increases. Moreover, the machine causes the mixture evenly and thinly. Mechanized plaster walls and ceilings got great reviews just for material savings: almost two times in comparison with execution of these works manually.

- Trim speed. With mechanized handling equipment causes a solution on a wall much faster than people – regardless of the amount of work.

- Maximum adhesion. Due to the mechanized method of plaster is best grasped and penetrates the wall. This happens due to the fact that the solution is made from high-quality fine-grained mixes and is discharged under pressure.

- The prepared composition is always enough. Manual plaster walls a solution it is necessary to prepare and apply in small portions, because it dries within the hour. In mechanized method, the solution is constantly mixed and not dry. This is allowed to cook from the correct amount of solution.

- The use of environmentally friendly materials. Plasters for walls mechanically do not contain harmful toxic impurities. They can be used for the walls, even in schools, kindergartens and hospitals.

- When using mechanized equipment in the future, virtually eliminated the possibility of subsidence, cracking and stains.

If to take into account the numerous reviews, the plaster walls in a mechanized way has only one drawback – the high cost of mechanized equipment. But because to buy mechanized equipment to furnish their own apartments unprofitable.

The technology of mechanized plaster walls ↑

Plaster mechanized can as beacons, which are put around the perimeter of the wall, and «the eye». In the latter case, it is necessary to conduct alignment level. Depending on the surface condition and the wishes of the customer, the plaster should be applied with thickness from three to twenty millimeters. After that, the wall is aligned and cemented.

Preparation of walls to the processing ↑

Before the plaster is mechanized is necessary to clean the wall from foam, masonry mortar, sagging of the concrete and joints if they are more than ten millimeters. Metal parts must be cleaned, and if they protrude above the surface, then remove. Areas that are not fixed, you must either remove or fix.

Then the wall is checked for vertical and horizontal. For the first test use of the plaster level with a length of two to three meters. The second validation is performed by means of a cord and template. The corners of the room check using angular templates, and corner rules. Validation will help determine the most protruding place on the wall.

The next stage of preparatory work is the application of a soil mix wall. The primer will allow several times to strengthen the surface and increase the adhesive properties of the plaster, as well as prevent the appearance of fungal structures.

To choose quality and suitable for plastering of walls in a mechanized way the primer will help the following video tutorial

When the preparatory stages are over, on the outside corner set special beacons-guide. In order to secure the aluminum beacons, on the previously marked places put a solution.

Plaster ↑

Plaster mix mechanically applied in the following way. A worker picks up a mortar gun and holds it so that the solution came out at a right angle (perpendicular) to the wall. Distance to the wall must be from 10 to 20 cm Gun is held at arm’s length and turn on the air valve. It is recommended to fill in mortar joints with other surfaces as well as corners. And then apply the plaster on the main surface.

Leveling the surface ↑

Leveling solution and the formation of a smooth surface must be completed before the plaster will lose its mobility. This is best done immediately after the plaster of the wall. For leveling use trowels, and spatulas and rules.

After leveling the plaster needs to dry up a little. In order not to lose time for processing provisions the following sections and are fine-tuning the angles.

Pruning damage solution ↑

This procedure is performed fifteen minutes after leveling the plaster. Pruning of the solution required to bring the shape of the wall using a special trapezoidal rule (cutter). Don’t forget that on a curved surface allowable deviation from the shape of the template 2 mm and straight within 2 mm per 2 meters podgornyh.

In order to ensure that the solution can be cut, you need to make to it a rule and a little stretching. If the layer is freely cut, then plaster finish. But if the entire mass follows the rule, then you need to give the grout time to harden.

If the rule is necessary to make further efforts to remove the top layer, it means that the plaster had «dry». Scratches and small bumps, you can wipe with a sponge.

The selection of the suitable compositions for plastering ↑

When plaster walls mechanically apply liquid and dry mixtures. In addition, mixtures are separated according to the material composition of gypsum and cement-sand.

The first is used for interior decoration. They are typically used for work with the walls in the apartments. It is important to note that this kind of mixture is used not only for walls but for leveling ceilings. Its main advantages – it is fast setting and a large porosity. However, gypsum plaster is not suitable for rooms with high humidity.

Plaster facades in a mechanized way using cement-sand mixture. They feature high strength and resistance to precipitation and temperature extremes. Such mixtures and their cons: long drying time and the need for putty.

Both of the above-described construction mixtures possess a high degree of protection from low temperatures and improved moisture resistance. Also, they do not render the ravages of ultraviolet light.

In addition to the main components in the mixture you can add other substances to reduce drying time and improve the ductility.

Mechanized plaster walls, ceilings and facades allows to ease and automate the repair work. It allows to save the budget and reduce physical activity.

How to prepare mechanized plaster station for subsequent operation of the will know in next video