The contents

Most often in the documents, estimates, or technical specification that is associated with the repair work in the room, whether apartment or house, contains the following term – high-quality plaster walls. Such concepts, indicating a complex of technical operations, often not decode. Therefore, there are cases when the essence of these tasks is not clear, and often this moment leads to a misunderstanding between the employee and the customer.

It is important to know and have an idea of what needs to be done, how, and what are the requirements of GOST and SNiP, in relation to the execution of such works. This allows you to avoid all kinds of conflicts and to repair the dwelling at the highest level. This is what we will discuss in the article. You will learn the standards for quality plaster walls, how it’s performed, and what its peculiarities. It will also consider the SNiP (construction norms and rules) regarding high-quality plaster walls, the required layer thickness and the quality of the mixture.

Classification of plaster finishes ↑

On the basis of the Russian SNiP 3.04.01-87, which is called «Finishing and insulating coating», there are 3 class finishes surfaces of plaster, which differ in quality:

- A simple plaster wall decoration.

- Improved.

- High quality surface finish.

What is the difference between the classes of finish specified in SNiP? Each of them implies clear fulfillment of the rules and requirements of GOST.

A little bit about the layers of plaster ↑

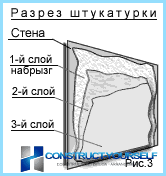

Before describing the types of plaster based on the quality, it is important to consider all of the layers of finish. You will need this information in order to understand the essence of the theme. What is the finish?

- First, spray base or prepare for further layers. For this purpose, the solution of a liquid consistence. It provides reliable adhesion (adhesion) of the surface with plaster. In addition, the compound gives the surface the property to repel moisture. Recommended thickness of layer 3-5 mm.

- The second phase, according to SNiP, starts with applying primer. What is its purpose? Them is aligned with the main plane of the surface. When performing work used a solution of pasty consistency. The thickness of this layer is 7-8 mm.

- The next layer is the finish coat. They line the small defects and smooth floors. This uses a mixture that has the consistency of sour cream. The recommended thickness of a layer in the area of 2-5 mm. Based on the requirements of GOST 8736-93, the fraction of sand particles must not exceed 1.2 mm.

Now let’s talk about how 3 different finishes, based on layers of ready mix.

Unlike plaster quality ↑

If we talk about the SNiP at plaster walls, it is important to understand what is the difference between the classes of finish. For example, the plain finish is most often used in basements, warehouses, lofts and outbuildings. Simply put, all non-residential premises, where to do a perfectly smooth surface is not necessary. The layers of finish the following:

- spraying;

- 2 layer soil.

This allows you to hide the main irregularities without additional labor and cost. The maximum thickness of plain plaster walls – 12 mm.

The improved plaster walls used in residential building, which is used by a person. It is important to make the surface smooth and beautiful, as she is constantly on the mind. It is applicable for private homes, apartment buildings, educational institutions, medical and public buildings. The coating consists of:

- spraying;

- 2 layer – primer;

- 3 layers.

Thus, you can remove the smallest defects and irregularities, making the surface smooth and beautiful. The total thickness of the improved plaster walls is 15 mm.

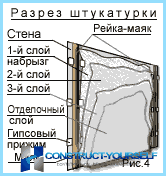

High-quality plaster surface the most technologically advanced. It is used for residential, public, educational and medical buildings, and office space, in which requirements for the plaster increased. In the context it looks as follows:

- spraying;

- 2 layer;

- 3 layer;

- the finish layer.

The maximum thickness of layers is 20 mm.

They are fixed in advance before starting work. As beacons can be used profiles from the metal or the solution itself.

What is high-quality plaster walls ↑

If improved plasterer designed to align the wall, then high-quality class can be used to align the walls and prepare the base for further processing. What?

- Application of paints.

- Wallpapering.

- Tiling.

- The application of decorative plaster, etc.

Thanks to the quality control specified in SNiP, to trim can at the highest level. It is important to consider the GOST regarding the materials used.

Take into account the order of operations:

- first plasterers ceiling;

- are processed the next wall, top–to-bottom;

- in last place are the floors.

But, the technology of performance of works is not all. It is important to figure out which is better plastering wall plastering and what are the requirements of SNiP and GOST finishing material.

The requirements ↑

To understand what is plaster for walls better, you need to familiarize yourself with the requirements of the material. They are all described in GOST 28013-98 (para. «mortars», section «Ls. specifications») and SNiP 3.04.01-87. Some of these technical requirements:

- the solution, which will spray and Prime the surface should easily seep through the mesh, with a cross section of cells 3 mm. the Mixture under the covering needs to seep through the cells, cross-section 1.5 mm;

- the mobility solution must be between 5-12 cm;

- unmixing of the solution, not more than 15%;

- the ability to retain water – not less than 90%.

As for the plaster, it is required to mix the sand, fraction of grains which are 1-2 mm. Mortars for ground spray should not have a fraction of sand is more than 2.5 mm and more than 1.25 for the finish. Additionally, the purchased plaster must have a certificate of quality and documents specifying: the date of preparation of the mixture, its brand, size, type of binder, the mobility of the mixture is in the price for 1 mTwo of the solution and its delivery.

It is important to know that plaster walls can be cement, sand, and maybe a plaster. Cement mortar is used for the treatment of external walls and wet areas. If you want to plaster the brick walls, it is better to make cement mortar.

The mixture of plaster used when it is necessary to align the walls inside the premises where the humidity is normal. The advantage of mixtures is that the work is done much faster as it dries it faster. Which one is better and will not say because it depends on the situation.

Conclusion ↑

Given the GOST on plaster walls, you can do high-quality plaster, through which all subsequent work can be done quite easily. This will not only simplify the task, but also will prolong the life of the finish. Then your effort will not be wasted. After reviewing all regulatory documents, everyone can work with their hands. Whatever was no problem to you, if you want you can do everything!