The contents

Polyurethane foam is one of the most commonly used materials for insulation of the facade of the house. It has excellent performance properties and easy to install.

That insulation spray polyurethane foam effectively — proven by numerous studies and reviews of builders, who had to deal with this material.

What is polyurethane foam ↑

Before proceeding to the description of the process of insulation by spraying polyurethane foam, you need more detail to understand the properties of the material. It is best to consider it as a certain kind of plastics.

Polyurethane foam or PU foam, which is used for warming by means of spraying, has a foamy structure. The main role in the composition plays a gaseous substance. Its inclusion in the General structure of about 90 percent.

Gas filled tiny cells that are formed in the process of insulating spray foam. Each cell is a stand-alone cluster. Due to this, it is possible to achieve high thermal efficiency. Actually, the other 10 percent are the walls of cells.

The Creator of the PUF is considered to be a German scientist Otto Bayer. There was an opening in the lab of Cologne. But to create foam, which is now used for thermal insulation of buildings by using the sputtering scientist and his team had to conduct many experiments.

PPU has lots of potential use. It is not surprising that there are many types of this substance. Also due to the fact that the material is quite simple to manufacture. Besides the technological process of deposition is a low cost.

The process of creating foam is fairly trivial. Two liquid component are mixed with each other. The result of their mutual reaction becomes a polyurethane foam that is used for insulation using spraying. In fact, you get hardened foam.

Depending on the properties of foam it is used in order to carry out spraying on different parts of buildings for better insulation. For example, one kind ideal to hold the insulation of Windows or doors, and the other ideal for treating brick or concrete walls, the third, in turn, is needed for pipelines.

The advantages of the foam ↑

Polyurethane foam is ideal when you need to carry out the insulation of such objects:

- attics,

- vertical building elements,

- basements,

- foundations,

- ceiling.

Polyurethane foam used for insulation, rot and endures a variety of external influences. It is sufficient to apply paint to spray to get a worthwhile result. Moreover, the substance is not toxic, provided that the elements used to create it comply with international norms.

The process of spraying polyurethane foam ↑

The technology of deposition ↑

To insulation with spray foam went as it is necessary, it is necessary to observe precisely the process. For its implementation will need special equipment, which will allow more efficiency and speed to insulate the walls.

Spraying is through a spray gun. It influenced fed under high pressure air is homogeneous mixing. It becomes possible thanks to the atomizer. Only after mixing is the coating of polyurethane foam.

Insulation spray polyurethane foam there is a thin layer. A stirred components reach the surface, and starts the reaction. It looks like a sharp increase in the volume of the foam. The substance soon hardens, forms a thermal insulation coating.

Density polyurethane foam that is spray insulation, depending on the consistency. Depending on the chosen parameters, the density can reach up to 70 kilograms per cubic meter. It is not necessary to make a substance with a density less than 25 kg/mThree.

In this case, when plated, there is an interesting feature of the PPU. The lower the density, the more amount of the substance. An important drawback of polyurethane foam with low density is that it does not tolerate mechanical load. Professional builders is not recommended to use a substance with a density below 25 kg/mThree for insulation.

As a veneer in most cases the use of polyurethane foam with a minimum density of 40 kg/mThree. This material does not require additional protection. It is enough just to paint, to give the building a finished appearance.

If you want to make thermal insulation of the floor, it is preferable that the density of the foam was not less than 60 kg/mThree. In this case, he will be able to withstand all mechanical loading. When you choose equipment for spraying, pay special attention to the feed rate to the atomizer. The device must have a controller. This allows economical use of raw materials.

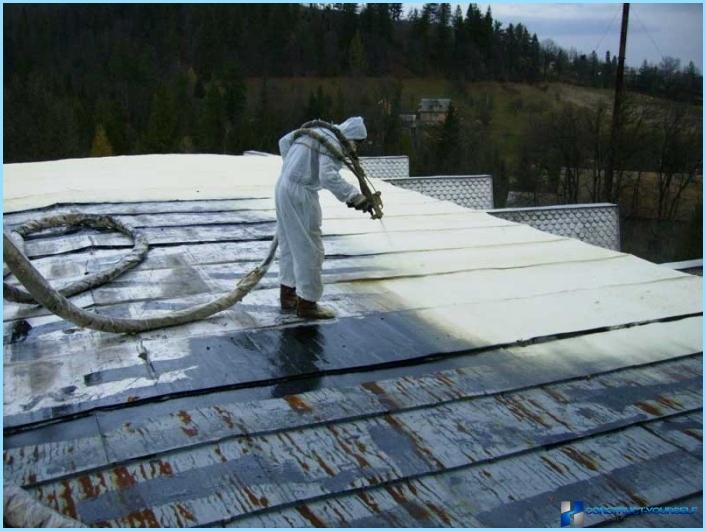

Treatment of roof ↑

A good example of the benefits that come with PUF insulation using spraying, is the handling of the roof. If to compare with traditional means, it is possible to save up to 80 percent of the time and 50% Finance.

But the spray foam on the roof has its own characteristics. Initially, you should cover the surface layer with a minimum thickness of 40 mm. While the estimated density of 60 kilograms per cubic meter and more.

It is very important to apply a coating of the waterproofing layer so that the insulation was really high quality and durable. For this, you need foam very high density. The thickness of the layer should be about 5-7 mm.

Comparison of polyurethane foam and extruded polystyrene ↑

To understand how spray foam effectively as insulation technology, it is sufficient to carry out simple mathematical calculation. In order to insulate the walls in 400 mTwo need about 20 cubic meters of plates with a thickness of 50 mm. as a material for comparison, take extruded polystyrene.

To cover the wall plates will need to follow the following steps:

- Rent indoor ZIL below for a few trips to transport all materials to the destination.

- Plates should be loaded so that they do not hurt.

- You must pick a place for temporary storage.

- To raise the plates in the forest and mounted on the walls.

- They are placed correctly to achieve high-quality thermal insulation.

- To handle the seams.

Especially difficult to properly convey the material to the installation site, where conducted high-altitude work. A very significant percentage of boards may be damaged. So when buying them you need to take a little more than is required for insulation.

For insulating the wall plates, not foam takes at least three days. Considering that you will work a staff of qualified personnel at less than seven people. Otherwise, the whole process can take from a week to several months.

Now as a comparison, take a standard spray insulation foam. The thermal conductivity of polyurethane foam is 0.27. This means that 40 mm of the substance by thermal efficiency equal to 50 mm of extruded polystyrene. To cover square 400 mTwo need 16 cubic meters. Taking into account that the density will be 40 kg per cubic meter.

In total 400 square meters can be coated with a substance weight of 640 kg. Such insulation will last you for years and will provide warmth and comfort in the house. All necessary for implementation of the plan can easily fit in a small «Gazelle» given the installation of foam and a compressor.

Now, with respect to human resource. This work can easily handle two people for seven hours. The insulation is monolithic without seams or joints due to deposition.

The results ↑

The process of spraying foam to insulate the roof, ceiling, basement or facade — fast procedure, which can be done with minimal time. Moreover, transportation of equipment and material is possible by a small-sized transport. It is also worth noting the high insulating quality of a substance.