The contents

In the construction business, the skill of the bricklayer is standing on the shoulders of the worker and largely depends on the quality of the materials used. The more the volume of construction, the more «walk» indicators of the composition of mortar for bricklaying. With the quality of the bricks is easier, it usually, «bake» on special lines according to the established technology and calibrated raw materials. While the properties of mortar mixtures strongly depend on the proportions of temperature, humidity and composition of the batch. The latter is also largely error-prone due to the human factor, because the dosing of the components have to perform manually. To check and correct, then there are mixed and in what proportion, is very difficult.

Universal prescription does not happen ↑

The composition and the proportions for the brick masonry is largely dependent on the objectives of masonry:

- For bearing walls of low-rise construction use of hard and malucci composition that provides high hardness of the weld in conjunction with the most common brands of ceramic red and white silicate bricks;

- For decorative brick masonry with minimal loads, but guaranteed no shrinkage or extrusion of the solution from the seam;

- Applied types of masonry brick ovens, chimneys, wells, internal partitions precast concrete boxes.

At the initial stage of construction are often faced with the problem of inconsistency of quality of cement its brand. Almost always purchased the material for the mix is brand a notch below. Therefore, proper selection of the proportions of the solution works, if be accurately determined properties of cement bases.

For this, often the composition is added an excess amount of cement, violating the proportions of the ligament. At first glance, the calculation is justified – reduced durability of the old cement needs to be compensated in proportion to its small abundance. But in reality effect is a little bit different than expected. Similar «supplements» can thoroughly ruin the mortar, greatly increases its shrinkage and uneven setting.

The proportions of mortar for masonry clay and lime ↑

The most affordable material to soften the binder is a clay, its an additive in a proportion of 1:3 mortar for masonry allows to obtain a robust and low-seam. The strength of such ligaments are slightly below normal, the design gains strength much more slowly than lime or pure cement set of standard recipes.

The use of clay is quite justified in laying a red ceramic bricks. Ideally, if the clay is added to the mixture, will be of the same fields as the raw materials used for «baking» brick.

In some cases, the mortar based on cement, sand, and clay is the only possible option bundles, for example – for the construction of furnaces, braziers and chimneys. But in these cases, simple recipe for mortar for masonry stove bricks, as a rule, no. Master selects the composition and the consistency of the solution according to individual abilities to be sintered without cracking the seam.

Common mortar for brick masonry ↑

The most simple, convenient and reliable for bricklaying has always been considered a three-component composition of cement-sand-lime proportions: 1 part cement-2/3 lime and 4 sand. Stir the mixture thoroughly and pour 1.5 parts water, mix until the consistency of sour cream.

The advantages of a three-component mortar for masonry are as high ductility and the ability to stick to any building material. Long term curing and low shrinkage combines well for thick or joints when laying ceramic bricks, cinder block with internal cavities.

Unlike mixtures containing proportions of clay, or pure sand-cement compositions, lime-containing mixture often forgive mistakes in the proportions of the mixture under the condition of exposure desired consistency of the binder. Plasticity and good spreadability of the solution allows you to securely hold build without shrinkage or cracking in the masonry.

Another unpleasant feature of these solutions is the proportion of lime efflorescence on the surface of clay bricks, especially in the case of using facing brands material.

Cement-sand options ↑

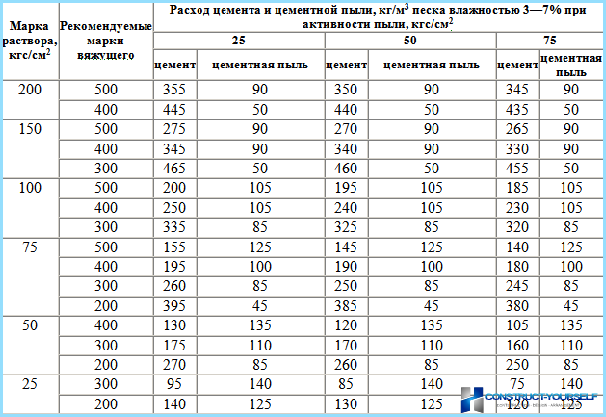

Most often the exact proportions of mortar for masonry brick cement sand required for thin walls, the thickness of single or half brick. The average ratio is taken from the table data, depending on the brand of cement. The tougher the desired solution and the higher strength requirements of the weld, the carefully selected components in the preparation of mortar for masonry brick, and kept the proportions. Bricklaying at this solution requires high speed operation and accurate eye in a dosage of the mixture in a thickness of a seam.

First of all, pay attention to the cement. The darker and fugitive cement dust, the higher its grade and strength. For most of the proportions one part cement selected five parts of sand. The best option would be river sand or washed thoroughly career. Not worth chasing a particularly small or large part, the main thing is to provide in the solution a minimum clay content and organic residues.

The amount of water required for kneading is selected in the amount of 0.8-1.0 volume of dry mix. To work with solutions of these recipes are extremely difficult, solution and so is not very pliable in the work, loses its plasticity within a half hour, the hotter the weather the faster the mortar sets. Often in such circumstances go to a conscious increase in the amount of water by 10-15%, so that the bulk of the solution was maintained its technological quality to produce 90% of.

Mixing of mortar for bricklaying begins with mixing of all components in required proportions in an exclusively dry form. The peculiarity of cooking hard cement-sand compositions is a condition shortselling long mixing in a dry form. The only way possible to ensure a high uniformity of distribution of sand and cement. After adding the water while stirring the mixture will absorb moisture, but to achieve the normal proportional distribution in wet intractable mixture will be hard.

Due to quick curing the mixing solution prepare in the small portions, no more than 5 buckets 1 Mason per hour. In this case, after each prepared portion of solution for masonry mixing tank, thoroughly clean from the residue, which was triturated various holes or cracks in the building.

Options for improving hard solutions ↑

Most often to improve the technological properties of the binder, without loss or reduction of strength of the seam, use a number of special additives. In industrial construction it can be patented surface-active agents: potassium and sodium salts of fatty acids, in powder form and liquid.

Most often additives are used in quantities of 1-5% of the volume of the batch to improve:

- The fluidity and plasticity of a solution, you can just pick the right texture, the hardness and strength of the weld will remain the same.

- Improve the frost resistance of the mixture, especially in wet weather with night frosts;

- Reduce shrinkage and prevent the separation of the mixing temperature variation or long-term storage.

Additive in solution ↑

Numerous experiments with additives in different proportions in the composition of the mortar allowed to pick up a few homemade recipes for sand-cement joint. Often as «brand» prescription manufacturers used recycled waste oil and fat products. For example, sulfate technical Soaps have a creamy consistency, perfectly soluble in water and can likely replace proprietary additive in the kneading.

The simplest recipe is the use of a mixture of soap and detergent in the ratio of 1:1, at the rate of 1 kg additives per 100 kg of mortar for masonry.

Conclusion ↑

Any, even the most proven recipe for bricklaying before any work will be checked for adhesion of the mixture of purchased cement and sand, called, «the shovel». A small number of components is mixed in the composition in varying proportions and is left to the day in a shaded dry place. Checking the strength of the solidified weld and shrinkage, an experienced Mason gives a nod to work with the solution.