The size and weight of any building material is the initial value for determining a set of auxiliary factors. The same sand-lime brick it is necessary to buy, to calculate correctly, hire a carrier with the movers and to deliver material to the construction site. All of this requires remuneration that are directly related to weight, size and amount of material.

Determine the size and quantity of silica brick ↑

Basic accounting work of a Mason is made of the calculation of the number of pieces of deposited material, at least – in cubic yards of masonry. Silicate brick in comparison with the ceramic unit is very heavy, higher physical activity and costs of its masonry. Prices can fluctuate and vary depending on brand, class average density, size and quality of masonry.

No one desires to calculate the after completion of the work, some sand-lime brick laid in the wall, what is the real material used, and how many rejected. So the size, brand and weight should be checked before work. This can be done in three ways:

- Tangenziale by measuring the linear dimension of height, width and length of construction material;

- To trust the information about the blocks of silicate on the label or labeling of the manufacturer;

- Weigh standard calcium silicate bricks per pallet, deduct the weight of the pallet and calculate the weight of one divided by the number of pieces specified in the invoice or on the label.

Thus in the modern marking of building material necessarily provides information about its name, brand, grade, medium density, frost resistance, increased size or single, information about the availability of special voids, photos. Information about the dimensions or weight of a standard single unit in the marking there, but it may be present as additional information from the manufacturer along with the gross weight of the entire contents.

In addition, current conditions of pre-sale preparation of the goods require packaging pallet with the material in a thick, clear plastic film that is difficult to pull a couple of units to measure or inspect.

Standard sizes ↑

By GOST №379-2015 are two basic size groups of silicate brick single and large, formerly single. The size both in length -250 mm, width – 120, height varies – increased construction material -88 mm, single – 65 mm.

These sizes have all kinds of facial and raw materials, regardless of the presence of voids or decorative elements on the front surface.

Opting single or magnified material is often done for reasons of ensuring attractive appearance of masonry. Single unit easier, and the clutch often looks spectacular, while the single material of silicate allows to increase the speed of erection of walls almost doubled with only a small amount of mortar on the seams.

Weight silica brick brand specific ↑

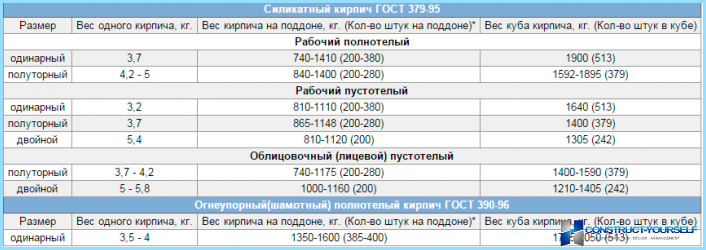

The most difficult and poorly controlled parameter of the silicate material is its weight. It is known that the average weight of a single instance of an ordinary brick can vary from 3.2 to 3.7 kg. Single instance average pull 4.3-4.8 kg, depending on design factors.

Depends on what weight ↑

If you ask for and check the weight of a silicate brick, and how not as described, you must consider the following factors:

- The standard identifies seven major classes average density of the material, which can be selected by the manufacturer depending on the used raw material from 1000 to 2200 kg/mThree;

- Within one class of sand-lime brick density can vary by 50 kg for a cube of the material;

- Different storage conditions materials of silicate have different humidity material and different weight.

The most popular among options of silicate materials for private construction are:

- Increased or Queen-size material with 20% of the volume of voids in the form of small cells with a class of the average density of 1.6. This durable, lightweight material with relatively good heat insulating characteristics. Building the main walls of two-storey buildings;

- Facing a single option class, of average density 2.0 with gypsum compound and hydrophobic impregnation.

The choice of silica brick based on the weight ↑

The weight of the instance material from silicate and its strength – is absolutely related things. Strength is largely determined by the degree of grinding of initial components and raw materials. The finer fraction of sand and lime, deeper and more thorough the mixing, the denser is obtained silicate mass of brick and above its weight.

In the production of such material is difficult, the process of autoclave processing requires increased costs for providing necessary strength of stone, the production takes more time. But in the body of the brick is much less air pores, devastatingly affecting the service life of silicate material.

This is due, primarily, with deep wet material. The more pores and cavities in the body of the material of the silicate, the more moisture it can absorb. It’s not necessary to leave the bricks in the rain or submerged in water. Very good, almost like a sponge, the material of the silicate mass can absorb moisture from fog, condensation and damp, especially from wet soil.

The more surface area contact, the faster the process of getting wet. And polyethylene packs on the pallet may not stop this process. Rather, it protects from heavy rain and preserves the appearance of the brick from contamination. Therefore, the purchased material from the silicate should be stored in a dry, ventilated place.

Very good for hydrophobic impregnation, but it lasts for a maximum of three to four years, the hotter the climate, the faster it disappears the repellent effect.

The standard defines the minimum absorption for silica brick of 6%. In practice, the maximum water absorption is 8 –for heavy and dense bricks to 14% for light and hollow. This means that half the sample weight 4.3 kg will be able to dial additional 0.5 kg or liter of water. Theoretically, being in the rain for a long time, a bundle of new material can put at least 10%.

Accordingly, you increase transportation costs, but, most worryingly, instead of the thick heavy option, you can buy wet light sand-lime brick and not even know it.

Most often, the weight of the block or stone are calculated as the mean value from weighing a small batch of ten pieces.

In addition to the density and water absorption, by weight silica brick is affected by the number of cycles of freezing and thawing, «experienced» material. With every new cycle of the external front surface is subjected to flaking and shedding. Standard requires that at a specified rate of frost resistance, for example, the smallest of the available – F25, twenty-five cycles the weight loss of the material did not exceed 5%.

Conclusion ↑

The weight and dimensions of sand-lime brick requires an individual control, at least within one packet. This will avoid losses associated with unscrupulous manufacturers of materials from a silicate-masses and that most importing substandard or counterfeit goods.