The contents

Since the construction of a private house or cottage, you need to ensure that building materials meet mandated requirements, must withstand a load. To ensure that the construction process does not escape the pitfalls of does not conform, to not have to redo your work and fix errors before starting work, must first get acquainted with the technical characteristics of building materials and their purpose. Than more you think over all the details of the future construction, the better the result is a durable, beautiful and warm your home or cottage.

What good is a silicate facing brick ↑

Appearance built care home owners, no less than interior decoration and errors in the veneer will be more than one year «cut eye» and on my nerves. Therefore, the choice of veneer should be approached very carefully and prudently.

The important point in the choice of materials is the choice of cladding material. Silicate face brick, its parameters are not inferior, and in something and exceeds ceramics.

Facing silicate brick is good for outdoor decorative surfaces of the walls. Among the advantages of silicate veneer:

- High density and strength of the material;

- Low costs in production associated with no roasting operations;

- Stability of the geometrical sizes;

- Sand-lime basis has no significant effect on pigments;

- On the colored surface does not appear unpleasant surprises in the form of efflorescence.

Facing silicate brick can be cut, drilled, rough order of magnitude better than ceramic material. In the capable hands of silicate material can emerge in the most sophisticated architectural forms.

Over time, the silicate-based cladding material becomes stronger, but only in the absence of regular becoming soaked brick surfaces. In the case of point erosion with the formation of chips with a smooth sharp edges of the front surface of the brick unit. Smooth, slightly rough surface becomes rough and coarse and full of large pores and caverns, which are deposited dust and dirt, giving the color texture gray earthy hue.

Most often it affects the upper rows of brick, sheltered from sunlight and wind the eaves of the roof.

Requirements for the quality of the facing silicate brick ↑

The surface of the bricks should be smooth, have no visible defects, chips, cracks, foreign inclusions, dents or bumps or any other defects. For the cladding material be sure the proper geometric shape. Quality material should not be anti-aliased edges, rounded corners, chips, nabityh places. Any defect of the facial surface will ruin the aesthetic and decorative appearance of the lining.

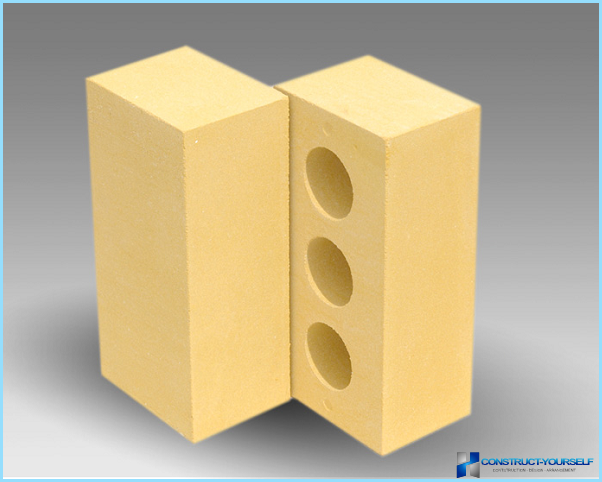

Obverse silicate brick, used for lining, depending on density, may be the following options:

- Hollow, new instrumental with cavities of a certain size, often finds application as a facing material. It has less weight, which facilitates the laying process and gives less load on the Foundation. Moreover, due to the presence of voids inside the bricks, air-filled, hollow material has a lower thermal conductivity, so it can be used for thermal insulation of walls;

- Monolithic, has a higher density than the core. It is stronger hollow, but has a large specific gravity, the heavier the installation, the wall of solid block gives more pressure on the Foundation. But in terms of strength and frost resistance it is superior to the hollow.

Size silicate bricks in accordance with the requirements of GOST positioned in three versions: single, Queen and double.

Single facing of a silicate brick is hollow, weighs 3.2 kg, and full-bodied weight – 3,7 kg. the dimensions of both are the same: length 250 mm, width 120 mm, height 65 mm.

One and a half brick is also divided into core, weighing 3.7 kg and full-bodied – from 4.2 to 5 kg. the Length and width of one and a half brick are the same as single, height 88 mm.

Double cladding silicate block due to the large mass of 5.4 kg produced only hollow. It has the following parameters: length 250 mm, width 120 mm, thickness 138 mm.

Can also issue facing silicate blocks of irregular shape, but only for a specific order, as well as a special stone, the purpose of which – the facing of round shapes, arches, beveled edges and other options.

Facing silicate brick production and technical characteristics practically does not differ from an ordinary material. However, for the price it is more expensive than the average, due to heightened quality requirements, so it makes no sense to use it for walls, which will then be plaster.

Most often a silicate cladding block is available in white or painted in soft colors. White silicate bricks can optionally be tinted a variety of colored impregnation, but only with subsequent processing of fixing the hydrophobic composition.

Color range of products is small, since the composition of raw materials for the production of silicate bricks include lime as the main component of the mixture. Because of this, the coloring components you can only use mineral pigments, resistant to alkalis. Therefore, the color range of facing silicate brick is quite poor in comparison with other cladding materials.

Possible variants of colouring of facing calcium silicate bricks in these shades:

- yellow can be Golden or pale orange;

- red;

- various shades of brown;

- black (or dark gray);

- «ivory», is the most popular color;

- blue;

- green, rather reminiscent of a swamp color.

Silicate mass may partially absorb the moisture and color pigment from the binder composition, thereby distorting the smooth shade veneer.

Options with profiled outer surface ↑

A modern gamma of the facing silicate brick includes items not only with a smooth outer surface. The market began to appear the silicate facing bricks with an interesting embossed surface.

Imitation of natural building materials ↑

Options relief surface represent imitation of natural stones «crushed stone» or imitation of the old Palace of stone «antique». Also produce bricks with a surface resembling wood «oak bark», this surface goes well with the red and brown colors of the brick. Surface «cane» simulates a vertically placed thin sticks, use brown shades creates a texture similar to wood material. An interesting variant of the textured surface produce silicate bricks surface «bug», correct embossed pattern that resembles the surface of the turtle shell.

The ability of the facing silicate brick «to keep the relief» the front surface allows you to prepare the whole mosaic composition. The use of special colored masonry mortars and protective mastic provides wide possibilities in decorating individual areas of the building.

Some of the shortcomings ↑

Cost painted and textured silicate facing brick will be more expensive than the usual white with a smooth surface. It’s heavier and denser than ceramic, does not like moisture, keeps the heat is bad and too having a good noise and sound. For cladding materials, it is not so serious disadvantages compared with the merits.

And yet, facing brick on a silicate basis is considered the most pure in the radiation and Toxicological terms, of course, if the sand for its production was chosen in accordance with the technological conditions of production.

Conclusion ↑

Decorative silicate bricks above the ceramic. To give the finish greater expressiveness can be combined in the veneer of various texture and color materials. Their combination gives the appearance of building individuality, allows to obtain the result of facing his own, unlike any other home design. Through play of colors in the veneer can visually increase the height of the building, or to allocate separate structural elements.