Any major construction going on in the private economy, begins with evaluation the required number of bricks usually come from the cost and availability of material. In regions with difficult weather conditions – strong frosts and long winters in most give sympathy silicate brick, and are often right in choosing.

Queen-size or single material to choose ↑

Silicate brick thick, a size and one half 250x120x88, formerly officially single, gradually displace from the market of building materials of its popular sibling – single – 250h120h65. The cause of the changes, as explained by experts, is the desire of the population to combine absolutely opposite things – strength, low cost material and reasonable ability to retain heat.

Compare the advantages and disadvantages of conventional sand-lime brick, size 250h120h65 and thick, a size and one half 250x120x88:

- The simplest calculation shows that the number of pieces of the thickened less than the number of standard size is about 1.35 times, and therefore, the walls of the house will be built faster;

- To win on paying the masons laying block and one half 250x120x88 is unlikely, the number of pieces of material is less, and weighs more. The same can be said about transport costs, for carriers it is important not the number of pieces of sand-lime block, and the weight of the load. Regardless of the type of stacked silicate, the total amount of walls will remain the same and the total weight of the silicate brick is not going to change.

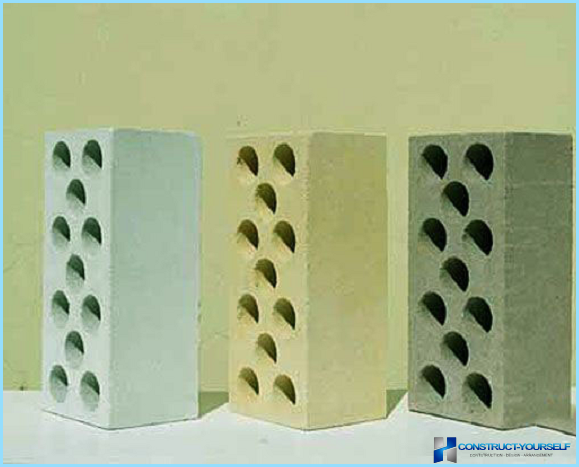

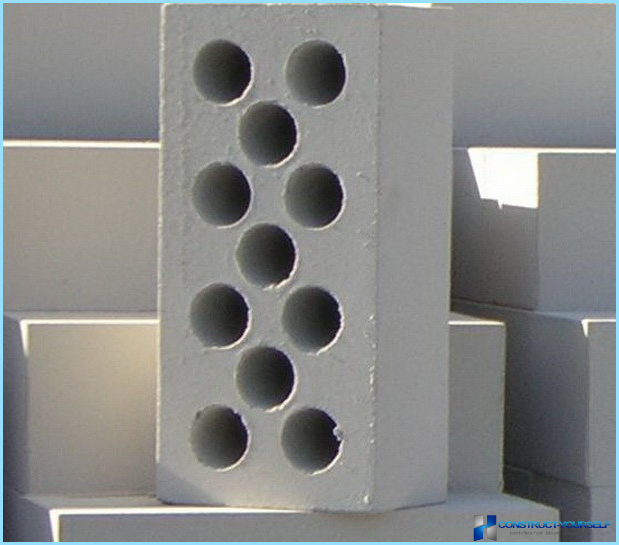

- Winning can occur if you use a silicate material size and one half 250x120x88 made with artificial voids. The standard volume cavity in 30-40% of its weight will be the same single solid block, and the insulating properties at 40-50% higher.

- The cost of the thickened silica brick and one half 250x120x88 at least 20% above the single brother, for reviews of builders, it is not always looks more attractive in masonry due to its size.

The last factor is a matter of personal preference of the customer. Manufacturers of half brick offset the recent lack of issuance of special options fittings and tiling. On the market there are color options of sand-lime material colored mineral compositions in black, blue, white colors. The most popular color for a ceramic fiery red stone. There are variants of silicate blocks with a beautiful chipped front surface, imitation natural stone material or debarked logs.

Properties of silicate material and one half 250x120x88 ↑

The properties of the silica material above and one half 250x120x88 single and even ceramic. Before comparing brick and one half 250x120x88 with his single brother, please explain why half of silicate material have certain advantages over ceramic block.

Problems ceramic competitor ↑

Quality ceramic stone is 80% dependent on the composition of the clay from which it is baked, and 20% from the manufacturing technology or the level of technological sophistication of the process. A high level of production depends on the availability of expensive modern equipment, which in modern conditions «afford» only big and serious manufacture. But today’s powerful high-quality deposits of clay or developed, or elaborated upon. The rest – small and scattered fields, with a mass of impurities the clay. Therefore, the quality of the brick, previously proven in the market may suddenly «to isogenics» to the limit.

Unlike ceramics, silicate material requires only quality cleaning, it is obtained artificially, or synthetically, its quality is stable. Moreover, modern methods allow to considerably increase the density of the silicate mixture and to increase the number of porous cavities, making it «fishnet». GOST silicate brick and one half 250x120x88 does not restrict the manufacturer in this matter, if only the wall were not less than 10 mm, and the strength corresponded Marche.

Where to use single and where single silicate brick ↑

First of all, the parameters of silicate bricks and one half 250x120x88 allow you to take the material and put it in the clutch with one hand. The strength and length of the fingers of an adult missing, but to the limit. Even harder to do it in canvas or textile gloves. The weight of a full-bodied single brick and one half 250x120x88 big – 4,3 kg. So working with him is hard, although the seams are thinner and smooth.

From the practice of masonry of silicate bricks had long been established:

- One and a half brick 250х12х88 successfully used in high-rise and low-rise buildings with wall thickness more than 50 cm;

- When choosing a brick for a specific thickness of the masonry to come primarily from the need to avoid excessive wall thickness due to the large size of a brick and excess amount of ranks because of the small size of a single brick;

- The outer row of sand-lime bricks 250х12х88 should be hollow and better – facing if the wall of sand-lime stone has additional insulation, all masonry is a silicate material 205х120х88, if conditions allow strength;

- Internal partitions and supporting structures are performed only from a single solid material.

For rapid laying is required only hollow half block and one half 250x120x88. Its weight varies depending on density and quantity of voids between 3.5 to 4.1 kg.

Conclusion ↑

For chipped broken bricks can be used to roughly establish its quality. If in 3-4 halves of 10 was discovered inclusions of pieces of clay, sand or unreacted lime material shall be tested for strength, if necessary – immediate rejection.