The contents

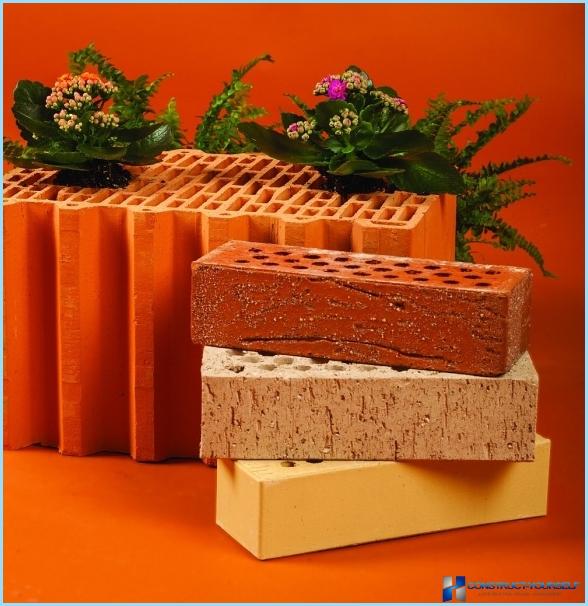

One of the most popular building materials is ceramic or brick red. It is used since ancient times, but remains as high in demand these days. Put it in the wall for various constructions, make Foundation, build furnaces, etc. the popularity of the material gained by low cost and in a number of positive properties and qualities.

It is noteworthy that due to the standard size red brick, builders can easily calculate the amount of material required for a particular job. In this article, we’ll talk more about the red bricks, its properties and characteristics.

The types of ceramic products ↑

For a start, it should be noted that the red bricks are made from clay by shaping and firing at high temperature of 1000-1100 ?C. With this great range of products you will not find, as among the main types it is possible to note only 3 types of red brick furnace:

- Plain red.

- Facing red.

- Special refractory.

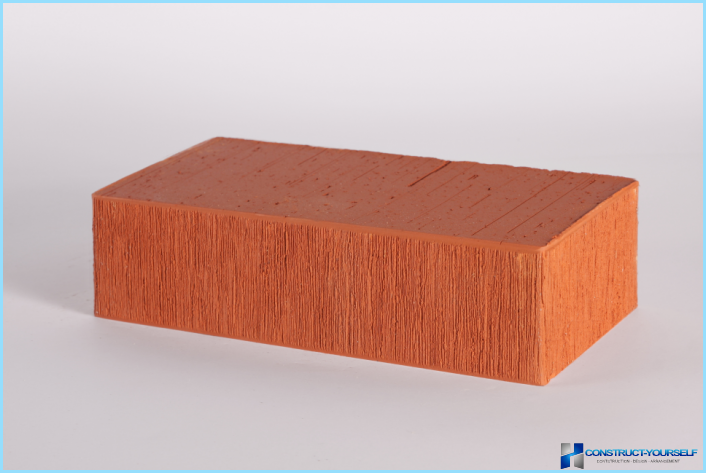

Ordinary block – the cornerstone, the one we all know. Because of it, walls going through walls. In the end, it revet a particular material, depending on the desire. Interior walls are also made from it. With regard to load-bearing walls to brick buildings, it is laid across the thickness of the walls, except the front row. To give the building a refined look, use the following type – face brick.

It can be called a purely decorative material, used for cladding exterior walls. Its price is much higher, so should work with it carefully. He put in a half-brick on the outside of the building.

As for the third type, they are made by special technology and is able to withstand the constant influence of high temperature. That is why they are used for masonry stoves, chimneys and fireplaces.

The size and content ↑

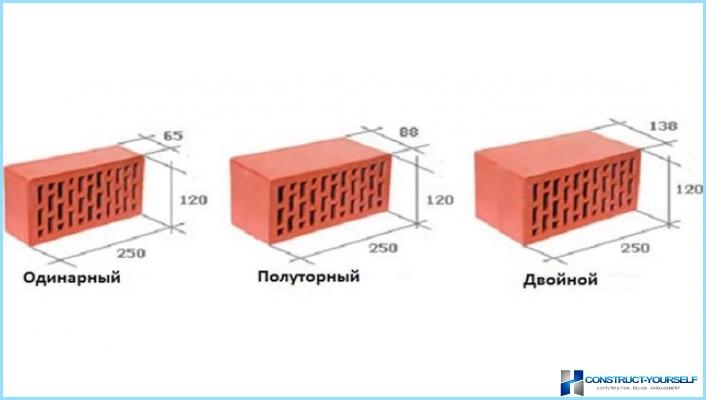

Also important is the size of the red bricks, as well as its content. As for the size, it is a standard and measured in three dimensions: length, width, thickness. According to GOST 530-2007, the dimensions of the products are:

- 250?120?65 mm. They are called single. The marking consists of 2 letters NF, which means the normal format. Such bricks are best suited for masonry of any walling.

- 250?120?88 mm. They are called semi-double, are labeled 1,4 NF. To reduce the overall weight of the masonry, use hollow blocks.

- 250?120?138 mm. They are called double, are labeled 2,1 NF.

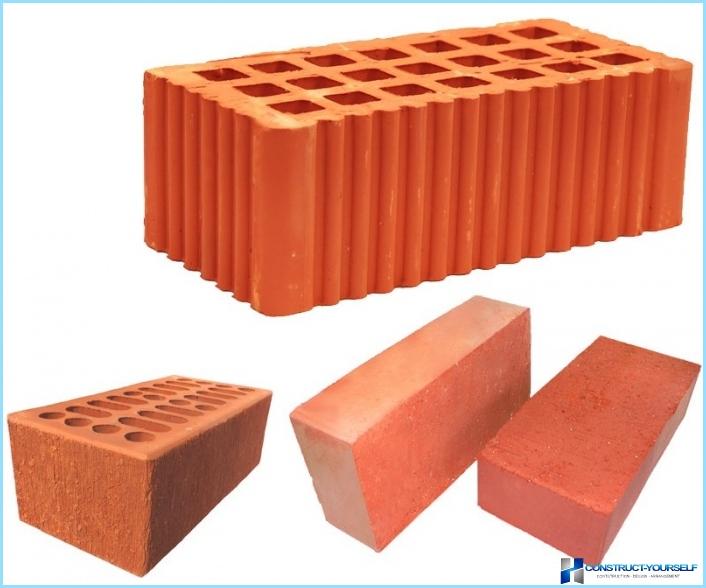

These are standard values which must be respected by the manufacturer. But, you may have a logical question: how much weight the red brick? Here the importance is not only its size but also filling. According to the method of filling there are two types of products:

- full-bodied;

- hollow.

How do they differ from each other? Full-bodied red brick is made of one piece, without through holes and cavities inside, but the hollow has them. Due to the space inside the weight of red brick much less. Also, the production of such bricks is less raw materials, reducing their cost. In addition, the presence of holes allow the bricks to better salivates with each other, as the solution penetrates into the cavity, firmly tying the bricks in all directions. As a result, they will not move. Among the shortcomings, core products have a lower density and strength, but all can be compensated mortar, which will require more than conventional brick.

What is all this? From the holes in the brick or not depends on his weight. For example, let’s consider the effect of voids on the ground.

- The weight of the red brick 250h120h65 of 3.5–3.8 kg per piece.

- The mass of single solid – 4-4,3 kg.

- Double can also have a mass of 6.6–7.2 kg.

Accordingly, total weight of hollow products will be much lower.

- Weight red hollow brick 250h120h65 equal to 2.3–2.5 kg.

- Weight of single block whose size is 250?120?88, equal to 3-3,3 kg.

- 4,6–5 kg – weight double hollow brick.

But the size, weight and the filling is not all performance. Another important point is the density.

Density and conductivity ↑

This indicator is measured in kg/mThree. Please note that the larger pores in the material, the lower its density. Accordingly the lower the density, the lower thermal conductivity of all brick construction and its acoustic properties. Here, the correlation of these parameters. To cite specific figures, the solid red brick will have a density that is around 1600-1900 kg/mThree, and the core has a density of 1200-1500 kg/mThree. It turns out that hollow blocks have better thermal insulation qualities.

Everyone knows that the bricks have a good thermal conductivity, capable to retain heat in winter and keep cool in the summer. What is the heat transfer coefficient has a red brick? The transfer coefficient is a parameter that indicates the amount of thermal energy needed to overcome the brick wall thickness of 1 m at a temperature difference of inside and outside 1?C. the higher the number, the lower thermal conductivity characteristics. This affects the thickness of the walls in the design. For example, solid products have a thermal conductivity of 0.6 to 0.8 W/(m·K). Core have a thermal conductivity of 0.5 W/(m·K). Therefore, for the construction of buildings anagramming is advisable to use the core product.

Ecological purity ↑

Brick with confidence can be called an environmentally friendly material, as it consists of natural, high quality and safe for human and animal components. It is based on clay, which is subjected to heat treatment. No toxic materials, mixtures and additives are not used. But what about it red? It is obtained by adding artificial pigment? Not at all. The color of the product due to the hue of the clay after firing. That’s why you don’t have to worry about the purity of the material. It can be called 100% organic.

Soundproofing ↑

Another important indicator. No one wants to live in the house where you hear any movement outside. Ceramic bricks are able to absorb sound waves, which corresponds to SNiP 23-03-2003. It is clear that to measure up to the cork or wood is not necessary, but if you compare the bricks with concrete, at first the absorption of noise is much better. If you take the wall thickness of which is 15 centimeters (a half-brick), it will mute for about 47 dB, wall thickness of 28 cm (1 brick), to cope with the 54 dB, and a thickness of 53 cm (2 bricks) will absorb 60 dB noise.

Durability and fire resistance limit ↑

The stronger the product, the higher its ability to resist various loads without damage. To determine the strength, take a look at the brand of the product. They are as follows:

- M300;

- M250;

- M200;

- M150;

- M100;

- M75.

These figures are not just because they represent the pressure, which can withstand a brick. The higher the number, the higher the strength and, consequently, price. This is an important indicator that you need to consider.

Another advantage of brick is resistant to open fire. This figure at the highest level, as the superior resistance of concrete, metal and tree, because it doesn’t burn. The building bricks can be under the influence of direct flame for 5 hours or more (concrete 2 hours, the metal – half hour).

Frost resistance and service life ↑

To determine the frost resistance can be the number of cycles in which the product is able to freeze and thaw, without losing the characteristics and integrity. The more cycles the better. From this figure, there are several brands of red brick: M150, M50, M30, M25.

If you want to extend the life of the material, buy a quality product. After all, the better the blocks, the longer it will be able to stand the building integrity. This indicator is not measured in tens and hundreds of years.