The contents

Most people associate concrete with very heavy material. It is not always convenient to use, and has a dense structure. With light concrete situation is quite different.

Nowadays lightweight concrete was progressive materials in construction. It is often uses in the construction of structures for various purposes. Concrete quality provide an opportunity to do better the acoustic properties of buildings and the influence on the thermal. And significantly reduce their weight and in the end affect the final cost. The use of such materials is especially important in the construction of houses in areas with risk of earthquakes, where the use of heavy concrete is unacceptable.

Lightweight concrete is mainly used for building insulation and load-bearing structures, and for creating decorative elements. This material helps to reduce the load on the Foundation, reduce labor costs and reduce transportation costs. View on the construction of houses of lightweight concrete at the link

What are the concretes? ↑

Quality concrete must always meet the state standard. The structure of the material in accordance with GOST 25192 can be different:

- dense. Ordinary lightweight concrete consists of fine and coarse aggregate, binder component and water. This kind of materials characterized by complete filling of voids between grains with a solution. The amount of air inside the mixture does not exceed six percent;

- macroporous. In this concrete binder component completely coats the grain filler. Air takes the material a quarter of the volume. To provide the best thermal protection for the premises from large-pore concrete, you will need to plastered walls on two sides;

- wire mesh or Parinirvana. This concrete is very dense and has a low conductivity. The pores are spherical cells with a diameter of one to three mm. Mesh building material has a sufficiently small volume mass, but good strength. These qualities, low price and ease technologies that is positioned cellular concrete as a modern building material for constructing walls and floors of buildings.

The aggregate in concrete is crushed stone, which could include limestone, dolomite and other components. Depending on the filler of release:

- slag;

- concrete;

- isobutan;

- agloporite;

- suggesition;

- perotbutton;

- thermostable;

- vermikulitobeton;

- seritonen.

Lightweight concrete produced from mineral or organic binders. From mineral use:

- cement;

- gypsum;

- lime;

- liquid glass;

- mixed components.

On appointment they are subdivided in the following types:

- structural;

- structural and heat–insulating;

- thermal insulation;

- heat-resistant;

- chemical-resistant.

Use products made of lightweight concrete, as well as various structures in various fields. For example, for the construction of bridges or transportation facilities. Also used in lightweight concrete industry, aquaculture, construction of farms for animal and elevatorstroy.

Porous concretes ↑

These materials are increasingly used in construction because they are durable and hardy. As well as resistant to moisture and is quite affordable. Moreover, thanks to the mineral-based concrete is considered environmentally friendly. In connection with the development of the production of porous materials used for the construction of modern buildings.

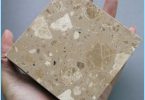

This is the most common type of lightweight concrete. Used in the construction of porous material in Ancient Rome, many centuries ago. For their production used the natural components. For example, a pumice stone or ceramics and clay from the pot.

Its a popular building material found in the second half of the twentieth century. It then began production of artificial porous fillers such as expanded clay, slag pumice and others. The placeholders which are used to create concrete are divided into two types: natural and artificial.

Made from natural materials such as:

- pumice stone;

- lava;

- limestone;

- rocks.

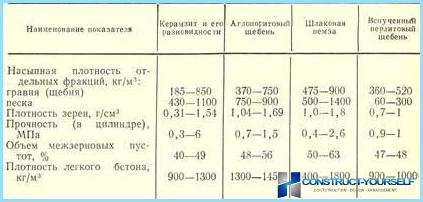

Artificial porous aggregates is the result of processing of natural raw materials with the use of chemical additives. Key indicators of the properties of fillers:

- bulk density;

- the strength of granules;

- the composition of the grain;

- water absorption;

- frost.

The process and technology of production of lightweight concrete ↑

The process of making this material is tremendously different from the works on production of heavy concrete. To create a quality product, porous fillers are stored in dry conditions, without access to moisture. Factions should be separate and not include mixing. This is unacceptable as is changing the composition of the product.

Transportation of aggregates is also produced with special care. It is impossible to prevent their destruction, mixing or hydration.

Lightweight concrete mixtures do most often in specialized mixers, which is not allowed, the process of disintegration components. Water should be supplied constantly while loading. The mixing time depends on:

- the operation of the mixer;

- speed;

- the density of the mixture.

The main packing method for lightweight concrete mixes – a vibration. When vibrating this material the mixture takes on a special character. The top float light grain at the bottom is cement.

Products made of such materials are often subjected to the steam treatment in a saturated steam environment. To lightweight concrete hardened faster, is to use Bespalova warming up in an environment of low humidity. This method helps to eliminate the humidity in the concrete, but no effect in the future on the strength of the material.

Basic properties of products from lightweight concrete ↑

The main difference between light materials from the heavy: the presence in the grain pore filler with both small and large. Compared to the cement stone, lightweight concrete less durable. But due to its structure, this material provides excellent adhesion with cement stone.

An important indicator of the quality of the material – its density. Different density in a dry condition and humidity. In the dry state, the figure standard and is constant. With humidity it all depends on how prepared concrete and how it will continue to operate.

Density depends on:

- the strength of the material;

- permeability;

- thermal conductivity.

There are the following types of lightweight concrete: from D200 to Д2000.

The reliability of the material depends on the quality of cement hardening condition. If the concrete is injected porous fillers, it affects its strength and significantly reduces it. A huge effect on the strength of the material having the presence of a large porous filler.

Water resistance and frost resistance of lightweight concrete no less than ordinary. However, the price is much lower. Basically lightweight concrete have frost in the range from F25 to F100. It is also possible to teach the material indicators F200, F300 and F400.

The water resistance of the lightweight concrete is high. Installed the following brands of lightweight concrete on water resistance: W0 2; W0,4; W0,6; W0,8; W1; W1,2.

If you want to save money on construction – lightweight concrete will serve as a great alternative to heavy structures.

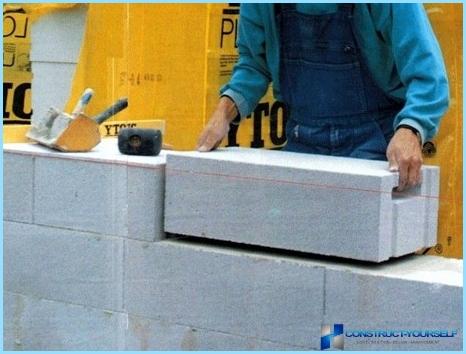

During the construction of the walls of lightweight concrete labor is reduced to twelve times, and the cost is below thirty percent in the amount of fuel consumption is reduced by 48 % compared with brick walls.

Main advantages:

- eco-friendly material;

- light weight;

- plasticity;

- can be used in the decor;

- does not absorb moisture and can be used in the construction of baths;

- refractory;

- hardy.

Concrete mixtures used in the decorations. For example, to create a beautiful arch, pillars in the Greek style, the framing of the Windows. The mass of options, if you make fantasy.

The use of this material allows to realize even the most bizarre ideas. In addition, all work can be done with your own hands. And ease of use will reduce the time of work.

This is a unique material that will not compare with anything else on the market. In the shortest time possible not only to build the room, but also make it a unique decor.