The contents

- Characteristics of precast concrete structures according to SNiP

- Requirements for the installation according to SNiP

- Test the performance of FLC for the SNiP.

Precast concrete structures are manufactured in factories and only then delivered to the construction site. On the one hand, due to the scale of production is significantly reduces the unit cost of production, on the other — the designer must set clear parameters of the future product.

Precast concrete reduce the time to build whole buildings, but the possibility of modification of products in the process are extremely limited and associated with considerable financial costs.

There are types of reinforced concrete structures, which are made only in factories. As an example — prestressed FLC. Generally, enterprises make only standard products. Of course, it is possible to order individual options, but the uniqueness has to pay. Conventionally, all of the production technology can be divided into three types:

- conveyor technology,

- flow-aggregate technology,

- bench technology,

For prestressed precast structures are used such methods of production: the tension in the concrete and the tension on the supports. Reinforcement is stretched Electromechanical and electrothermal method.

General characteristics ↑

Characteristics of precast concrete structures depend on the grade of concrete and type of reinforcement they use. Concrete possesses such quality parameters:

- frost,

- strength,

- high density,

- fire resistance.

The only disadvantage of concrete is poor resistance to stretching. To counteract used fittings. It can be made of composite or steel. The form may be different, but in most cases applies to the ribbed steel bars with a circular cross section.

The installation process ↑

At the beginning of installation check the condition of the already installed precast concrete structures. Further, the algorithm of the process depends on the type of FLC and the objectives pursued by the builders. Nevertheless there are points which are always present in the work:

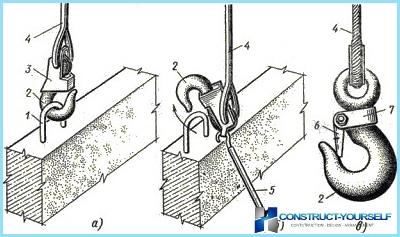

- Inspection of precast concrete structures, to install. Builders must ensure that the fixings are properly positioned, and corrosion-resistant coating is not damaged. Special attention is paid to rebar, it should not be damaged or deformed.

- Checked design and mounting holes. Their diameter should match the indicators in the project. To measure use the tape measure or meter.

- Prefabricated concrete structures are examined for cracks and sinks. The geometric shape of the product shall conform to design.

- After checking all precast concrete structures are cleaned. Deformed during shipment details straight. The influx of removed concrete and cleaned off the rust (if this was discovered).

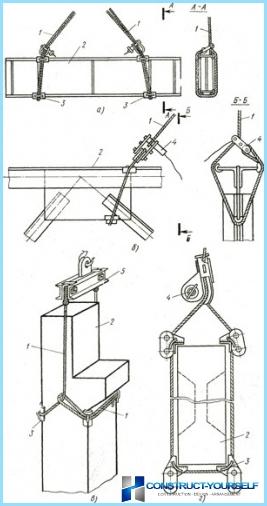

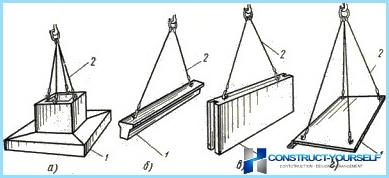

Prefabricated concrete structures in the process of installation can scrapomatic different methods. The gripping means may be in the form of beams, flexible lanyard or suction Cup grippers.

SNiP 52-01-2003 edited from 2012 ↑

SNiP is a set of rules that includes a set of standards and guidelines regarding the manufacturing, designing, installation and transportation of precast concrete structures.

Prefabricated concrete structures, in spite of high strength, must be transported in accordance with established standards. When FLC is designed, taken into account the impact of efforts that arise when lifting, transportation and installation. The load depends on mass and is calculated using these coefficients:

- 1.4 installation;

- 1.6 for transport;

- 1.25 the dynamic factor.

The latter figure illustrates the boundary the figures below, which factor in the calculation may not fall. Otherwise, the reliability and durability of precast reinforced concrete structures will be questionable.

A special place in the design process of precast concrete structures play a nodal and butt elements. It is from their quality affect the operational characteristics of the entire design team.

In precast concrete structures play an important role loops. When they are created according to SNiP 52-01-2003, decided to use hot rolled reinforcing steel. Her class should not be below A240.

If you have ever had to deal with monolithic reinforced concrete structures we know very well that they cannot be installed in freezing temperatures without special equipment. FFA is deprived of such shortcoming. According to the SNP they can be mounted, when it’s -40. This does not affect their performance.

Characteristics of precast concrete structures according to SNiP ↑

- Humidity level is medium or low, the type a closed protective layer is not less than 15 mm.

- In high humidity indoor — 20 mm.

- Outdoors — 25 mm.

- In the soil and the Foundation — 35 mm.

To achieve the desired qualitative indicators is necessary to precast concrete meets these characteristics. Reducing the protective layer of concrete is only possible with additional measures to protect.

If precast construction is a reliable protective layer to the reinforcement, there is a high risk that before the design team gets corroded. This jeopardizes the strength of the entire building.

Requirements for installation according to building codes ↑

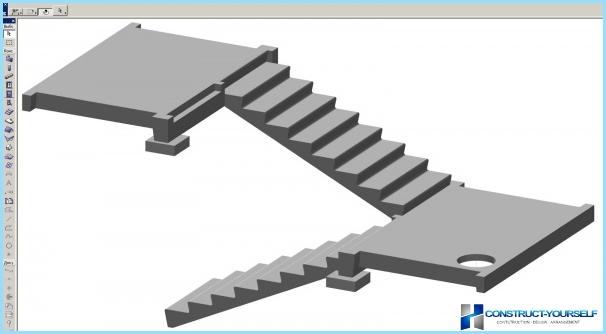

The building of the FLC, the role of the designer increases dramatically. It should, with the assistance of special programs to calculate in advance the parameters of the future structure. According to the characteristics of the plant will produced the desired shape and size.

Installation must take place strictly according to the approved plan. The document stipulates the order of the works and additional measures to ensure the desired strength. Prefabricated concrete structures are going directly to the object and set to put them in the project place.

Test the performance of FLC for the SNiP. ↑

Before you send the product to the customer or put it on the stream, is a set of complex tests. In the process tested the following characteristics:

- resistance against crack;

- operational suitability;

- General assessment of suitability.

Usually the party takes a few products, and they are subjected to different kinds of tests. The choice of the latter depends largely on the purpose of the precast concrete structures. The fitness assessment consists of indicators such as:

- the thickness of the protective layer;

- strength of welded joints;

- the geometric size of the cross sections and location of rebar;

- strength of welds;

- mechanical properties of rebar;

- size products.

On the basis of these indicators shall be assessed the entire party, and makes a decision regarding its suitability.

The results ↑

Precast concrete structures are manufactured in factories. At the time it gave a significant impetus to the overall industrialization of the industry. FLC can be installed in any weather, and the cost is at an affordable level.